ARBOR earns Taiwan Excellence Award for edge AI systems

ARBOR Technology Corp. has received the Taiwan Excellence Award 2026 for three flagship solutions – FPC-5211 series, IEC-3714, and IEC-G510. This recognition validates ARBOR’s exceptional innovation capabilities in compact, rugged, energy-efficient, and AI-communication ready – that represents ARBOR’s technology leadership globally. ARBOR Technology Wins Taiwan Excellence Award with High-Performance Edge AI Computing Solutions. ARBOR FPC-5211 series: ESG high-performance fanless edge computing system FPC-5211 series, winner of the Embedded World 2025 Best-in-Show award, redefines fanless edge AI computing. Built on the philosophy of “Zero-Carbon Smart Manufacturing, Edge Computing Excellence,” it combines Intel Raptor Lake processors with NVIDIA RTX-2000A GPUs in a compact, fanless design. The system cuts energy use by 70%, triples service life, and delivers military-grade reliability for smart manufacturing, AOI inspection, and smart healthcare applications. ARBOR IEC-3714: AI edge computing for smart retail solution IEC-3714 is a compact AI edge computing digital signage system delivering 34 TOPS of AI performance with four-channel 4K synchronous output. Powered by the Intel® Core Ultra processor, it runs four OpenVINO AI models—face, age/gender, expression, and object recognition—enabling real-time, AI-driven advertising, passenger flow analytics, and cashierless retail. Its ultra-compact 115.4×107.6×37mm design reduces equipment costs by 60% and operating expenses by 40%, setting a new benchmark for next-generation AI signage. ARBOR IEC-G510: ultra-slim AI smart digital signage player system IEC-G510 is the industry’s first ultra-thin player built on the MediaTek Genio 510 platform with integrated AI acceleration. Measuring just 20mm thick, it features an APU neural network processor for real-time facial and emotional recognition while cutting material costs by 35% versus x86 systems. With advanced thermal design and compact integration, it delivers high-performance, low-power AI computing ideal for smart retail and interactive advertising applications. Winning the Taiwan Excellence Award affirms ARBOR’s innovation and showcases Taiwan’s strength in smart manufacturing. ARBOR will continue to invest in AI and edge computing research and development (R&D), empowering global customers to confidently drive digital transformation. For more information, visit arbor-technology.com. The post ARBOR earns Taiwan Excellence Award for edge AI systems appeared first on Engineering.com.

Velotric early Black Friday Sale up to $600 off e-bikes, Rad Power RadRover 6 Plus at new $999 low, Heybike lows from $999, more

We’re closing out this week’s Green Deals with a full e-bike edition, led by Velotric’s early Black Friday Sale with up to $600 savings on a selection of models, like the Discover 2 Step-Thru Commuter e-bike at $1,899 and getting $120 in FREE gear. Right behind it is Rad Power’s RadRover 6 Plus e-bike at a new $999 low, as well as Heybike’s ALPHA All-Terrain Mid-Drive e-bike getting $266 in FREE gear at a new $1,299 low, and the Ranger S Folding e-bikes (750W and 1,000W) down at annual lows starting from $999 – but keep in mind that these two are only staying at these rates for four days – plus, other ongoing early Black Friday deals waiting for you below. And don’t forget about the hangover deals that are collected together at the bottom of the page, like yesterday’s full Rad Power Black Friday e-bike sale lineup, the Jackery early Black Friday deals + an exclusive solo deal, and more. Head below for other New Green Deals we’ve found today and, of course, Electrek’s best EV buying and leasing deals. Also, check out the new Electrek Tesla Shop for the best deals on Tesla accessories. more…

Teradyne unveils new ETS-800 automated test system for power semiconductors

Automated semiconductor test equipment firm Teradyne has launched the ETS-800 D20, the latest addition to its ETS-800 platform of high-performance test systems for power semiconductors. The Teradyne ETS-800 D20 has the flexibility to scale from low to high volume as device requirements grow. The new configuration is a dual-sector test head system that provides a flexible and efficient platform for all test insertions and package types. The system can be configured at low density for low volume testing using up to two instruments, or at high density for high volume testing using up to eight sites that can be tested in parallel, Teradyne said. The ETS-800 D20 can transition between platforms, leveraging the same tests, instruments, docking and software across all ETS-800 systems to maximize capital investment and factory floor space. Battery management systems in EV have a substantial impact on the vehicle’s performance and range, requiring accuracy. The Teradyne ETS-800 platform delivers the required current in the shortest duration simultaneously to measure ultra-low resistance, ensuring lower losses and less heat generation. “This new system offers a cost-effective and flexible solution for high volume and high mix/low volume device testing for the power semiconductors enabling today’s most critical systems and applications,” said Dominic Viens, VP and General Manager of the Power Test Division at Teradyne. “Its advanced features and compatibility with existing instruments and systems [mean] the ETS-800 D20 is poised to meet the evolving needs of our customers to help them achieve their production goals.” Source: Teradyne

Tesla (TSLA) shareholders officially approve Elon Musk’s 2025 performance award

Tesla (NASDAQ:TSLA) CEO Elon Musk has officially approved his 2025 Performance Award, a landmark pay package that could make him the world’s first trillionaire and make Tesla the most valuable company in the world by a mile. The 2025 CEO Performance Award was officially approved by Tesla shareholders at the 2025 Annual Shareholder Meeting. Elon Musk‘s landmark pay package As per Tesla, more than 75% of the shareholders approved Elon Musk’s 2025 CEO Performance Award. It was then unsurprising that the approval of Elon Musk’s pay plan received overwhelming applause from the event’s attendees. The CEO took to the stage with much enthusiasm, welcoming every shareholder to the event and dancing briefly on stage. Optimus also danced on stage smoothly, demonstrating its improved movements to much appause. Tesla Annual meeting starting now https://t.co/j1KHf3k6ch — Elon Musk (@elonmusk) November 6, 2025 Optimus can dance pic.twitter.com/i6PYIUxsSn — DogeDesigner (@cb_doge) November 6, 2025 Elon Musk’s 10-year targets To earn his 2025 CEO Performance Award, Musk would be required to grow Tesla’s market capitalization from about $1.1 trillion today to $8.5 trillion over the next decade. At that level, Tesla would surpass every major public company in existence. The compensation plan also requires Tesla’s operating profit to grow from $17 billion last year to $400 billion annually. Apart from leading Tesla to become the world’s biggest company in history, Musk is also required to hit several product targets for the electric vehicle maker. These include the delivery of 20 million Tesla vehicles cumulatively, 10 million active FSD subscriptions, 1 million Tesla bots delivered, and 1 million Robotaxis in operation. The post Tesla (TSLA) shareholders officially approve Elon Musk’s 2025 performance award appeared first on TESLARATI.

Tesla schedules Roadster unveiling event, and you won’t believe when it is

Tesla has tentatively scheduled its unveiling event for the Roadster’s next-generation iteration, and you will not believe the date the company picked for it. Tesla CEO Elon Musk said during the 2025 Annual Shareholders Meeting that the company is aiming for an April 1 demo event. Yes, April Fools’ Day. Tesla’s unveiling event for the Roadster Gen 2 is scheduled for April 1, 2026. Yes, April Fools’ Day. pic.twitter.com/sw09GUYFPV — TESLARATI (@Teslarati) November 6, 2025 Tesla originally aimed for its “most epic demo” to take place at the end of this year. However, the writing on the wall as 2025 winds down seemed to indicate the company was not quite ready to show off everything it plans to implement into the Roadster. Its capabilities have been teased quite heavily throughout most of the year, but the biggest hints came last week when Musk appeared on the Joe Rogan Experience Podcast. He said: “Whether it’s good or bad, it will be unforgettable. My friend Peter Thiel once reflected that the future was supposed to have flying cars, but we don’t have flying cars. I think if Peter wants a flying car, he should be able to buy one…I think it has a shot at being the most memorable product unveil ever. [It will be unveiled] hopefully before the end of the year. You know, we need to make sure that it works. This is some crazy technology in this car. Let’s just put it this way: if you took all the James Bond cars and combined them, it’s crazier than that.” The Roadster has been somewhat of a letdown, at least in its newest version, thus far. Tesla has routinely delayed the project, putting those who put lofty down payments on the car in a weird limbo, lost at what to do. One notable pre-orderer cancelled his reservation last week and got in a spat with Musk about it. Now that there is a definitive date for the Roadster unveiling, Musk and Co. should have a more definitive cutoff date for features and capabilities. Chief Designer Franz von Holzhausen said earlier this year that when they showed Musk what they had done with the Roadster, the CEO encouraged them to do even more with it. This delayed things further. Musk also said he believes production would begin between 12 and 18 months after the unveiling, putting it out sometime in 2027. The post Tesla schedules Roadster unveiling event, and you won’t believe when it is appeared first on TESLARATI.

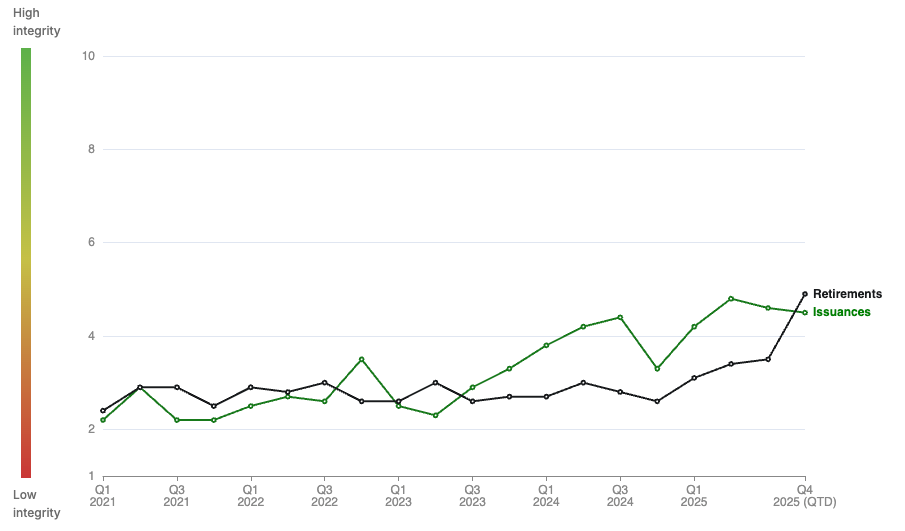

Carbon market turnaround continues as buyers eye more purchases

Is the carbon market emerging from its years-long slump? A series of new findings suggests it is. Buyer confidence, which had been severely dented by exposés of flawed projects, appears to be returning as market quality inches upward. The most recent data comes from a survey of businesses in 30 countries carried out by SE Advisory Services, the consulting arm of energy technology company Schneider Electric. Asked about purchasing plans between now and 2030, more than half of respondents said they expected to increase engagement with carbon markets — 29 percent moderately and 26 percent significantly. The shift is driven in part by the spread of new emissions reduction regulations, particularly in Asia, that allow companies to use credits to hit targets. “These early movers are building the inventories, relationships and capabilities they will need when voluntary becomes mandatory,” the report authors noted. Buying better Buyers, particularly those new to the market, are also using new quality signals. The Schneider report found that 55 percent of respondents looked for the Core Carbon Principles, a quality label developed by the Integrity Council for the Voluntary Carbon Market that rubber-stamped its first methodologies in summer 2024. Although the council’s decisions aren’t a guarantee of quality — several of its first approvals were questioned by independent experts — the label is considered a relevant part of a due diligence process nonetheless. Buyer demand for quality seems to be slowly shaping the market. The integrity of credits issued and retired has been trending steadily upwards since 2021, as measured on a 10-point scale used by Calyx Global, an independent rater of credit projects. Carbon credit quality trends A similar uptick was seen by the finance intelligence provider MSCI, which rates carbon projects from AAA to CCC. The company’s second annual report on market integrity, published in September, noted that 35 percent of credits retired in the first half of this year were rated BBB or above, compared with 25 percent in 2022. Higher-quality credits are also commanding higher prices, according to an index maintained by Calyx and ClearBlue Markets that offers tools to help companies navigate carbon markets. Prices for carbon credits in different quality tiers MSCI data aligns with this: Credits in the company’s high-integrity index traded at more than four times the price of those in its low-integrity index, compared with a two-fold difference in 2024. ‘Intractable’ problems Still, the most talked-about publication in recent months probably isn’t any of the above. It’s a review of the academic literature on carbon credits, by Joseph Romm at the University of Pennsylvania, which concluded that many popular offset types have “intractable” quality problems. Many in the industry said Romm’s paper flagged known problems that are being addressed by the integrity council and other organizations. Others — including the Guardian, one of the fiercest critics of carbon markets — cited it as yet-more evidence that carbon credits cannot be trusted. The carbon market may be evolving, but its ability to divide opinions remains unchanged. The post Carbon market turnaround continues as buyers eye more purchases appeared first on Trellis.

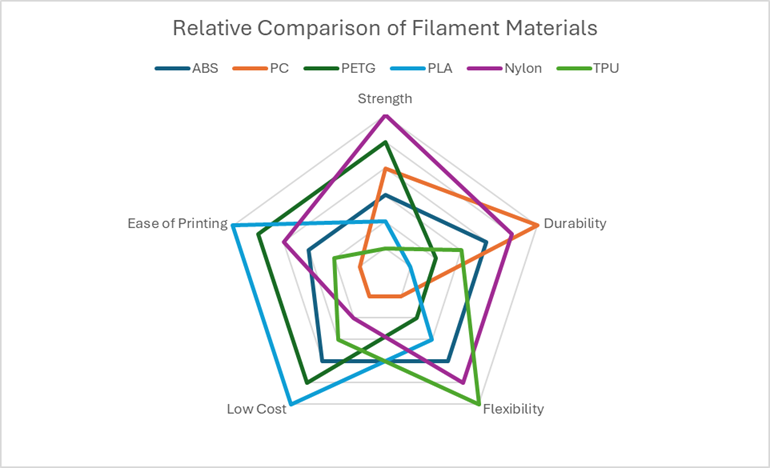

Selection advice for 3D printer filament

There are 3D printer filament suppliers all over the world (here’s a handy rundown of the largest commercial vendors compiled by Reddit user starbuck93), so it’s easy enough to find what you need. Of course, figuring out which material you need is another story. As with suppliers, there are numerous options for polymer materials in additive manufacturing (AM), which is similarly great for choice but challenging for decision-making. This short guide is intended to help engineers select the right 3D printer filament for their application by focusing on five core factors: strength, flexibility, durability, ease of use, and cost. To get started, here’s a relative comparison of six of the most common filament materials: ABS, PC, PETG, PLA, Nylon, and TPU. 3D printer filament strength One of the biggest differentiators between AM material options, strength in this context encompasses tensile strength and impact resistance—which apply to materials in many manufacturing processes—as well as layer adhesion, which is specific to additive processes. For material extrusion processes, such as fused deposition modeling (FDM) aka fused filament fabrication (FFF), the strongest material options are those which incorporate filler materials, such as carbon fiber. 3D printer filament durability Another important consideration when selecting among 3D printer filament options is durability, which includes its resistance to fatigue, heat, chemicals, moisture, and ultraviolet (UV) radiation. The last two points are particularly relevant for outdoor applications, but water resistance is also important when it comes to storing and preparing filaments for printing. For example, Nylon and PETG are both relatively strong and durable, but they’re also hygroscopic, and so require a filament drying to ensure quality 3D printed parts. 3D printer filament flexibility While the range of material options has expanded considerably over the last decade, the options for flexible 3D printing materials are still fairly limited, with TPU being by far the most common. Nylon and polycarbonate materials are more flexible than the more common and less expensive ABS and PLA, but they’re also more difficult to print. Generally speaking, the best option for 3D printing flexible materials, such as TPU, is to use a direct drive extruder, since it should reduce the chance of jamming. 3D printer filament cost The cost of 3D printing filaments varies widely, not only by material but also by supplier. As previously mentioned, PLA and ABS are by far the least expensive options but they both come with drawbacks in terms of their strength and durability (for PLA) or ease of printing (for ABS). In most cases, relative cost will likely be determined by the priority of the other factors on this list (i.e., how much you’re willing to spend in order to achieve your targets for strength, durability or flexibility) in combination with the number of parts needed. 3D printer filament ease of printing Compared to other 3D printing processes, material extrusion is relatively user friendly, which partly explains why desktop FDM/FFF machines are by far the most common in the consumer space. Nevertheless, some materials are much easier to 3D print than others, with PLA being the obvious favorite of amateurs. The reasons for this are indicative of the features to look for when evaluating how difficult a particular material is to 3D print: PLA has a relatively low printing temperature, good bed adhesion, and it’s generally resistant to warping. Generally speaking, the better a material’s mechanical properties, (i.e., its strength and durability), the harder it is to 3D print. The post Selection advice for 3D printer filament appeared first on Engineering.com.

VMAX VX2 Hub 33 MPH e-scooter review: Fast yet surprisingly stable – and affordable!

When it comes to high-performance electric scooters that are still reasonably priced, it’s a tricky balance. Most affordable scooters are underpowered and wobbly. The powerful ones often creep into motorcycle territory – with prices to match. But the VMAX VX2 Hub might just be the sweet spot we’ve been waiting for. It’s fast, it’s strong, it’s well-built, and most importantly – it actually feels good to ride. Let’s dive into what makes this scooter stand out. more…

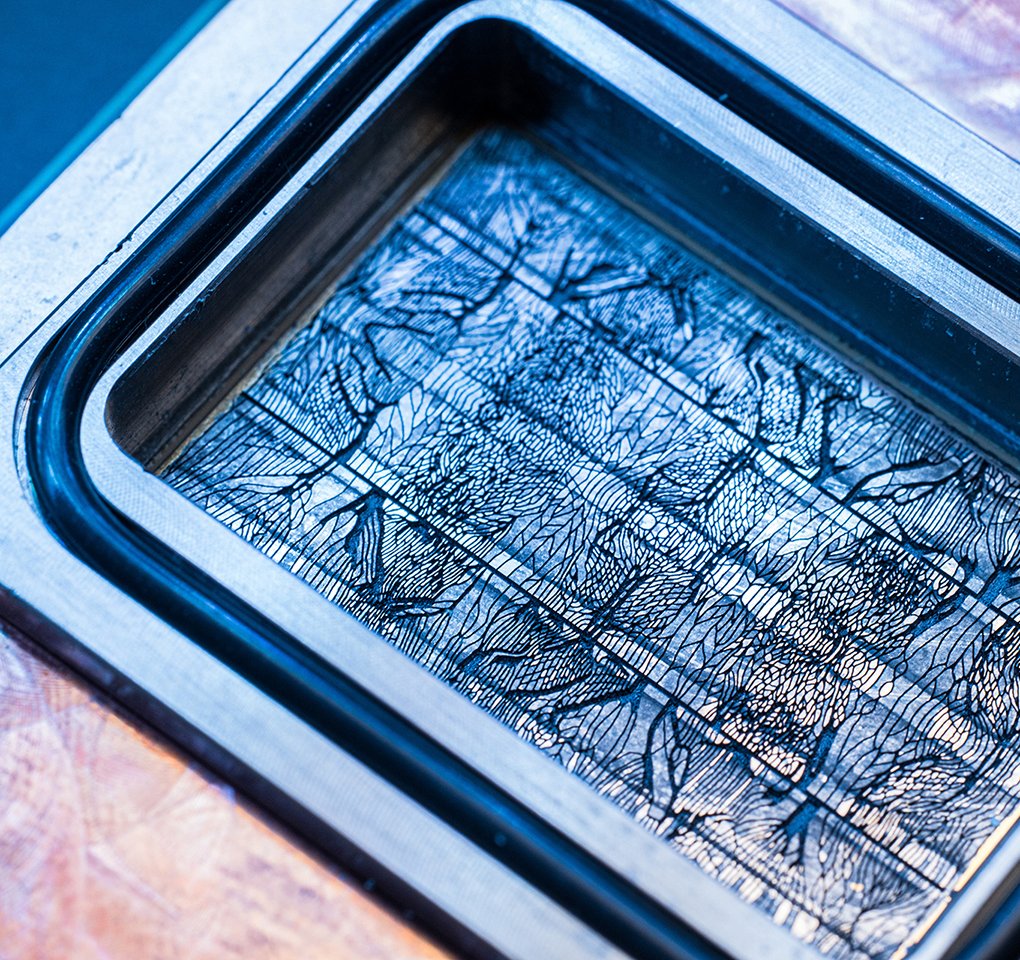

Fraunhofer IWU and Amsted Automotive unveil aluminum foam battery housings for EVs

Fraunhofer Institute for Machine Tools and Forming Technology (IWU) and Amsted Automotive have introduced an integrally designed battery housing utilizing aluminum foam sandwich (AAS) structures. The new housing features two solid aluminum sheets enclosing a core of closed-cell aluminum foam, aiming to advance electric vehicle battery pack thermal management and structural integrity. The AAS housing can be produced in several configurations. Fraunhofer IWU says options include pure AAS, AAS with infiltrated phase change material, AAS with an integrated cooling structure and AAS with both a cooling structure and PCM. The core innovation is the combination of aluminum foam and phase change material, which absorbs or releases heat by transitioning between solid and liquid states without significant temperature change, supporting efficient lithium-ion battery temperature control. Fraunhofer IWU says integrating PCM within closed-cell aluminum foam enables substantial thermal energy storage or release, which can help manage battery temperatures during operation or charging, a priority for EV manufacturers. Depending on the application, different versions can be tailored to provide structural support, passive thermal management or active cooling. To facilitate use in high-volume production vehicles, researchers are also emphasizing cost reduction. “We are increasingly using recycled material to produce the aluminum foam,” said Fraunhofer IWU researcher Dr. Thomas Hipke. “Not only is this significantly more cost-effective, but it also greatly reduces the CO2 footprint,” addressing both price sensitivity and sustainability demands from the automotive sector. Source: Fraunhofer IWU

Tesla’s latest Robotaxi job posting takes the whole program a step forward

Tesla’s latest Robotaxi job posting goes beyond what has been posted in the past and truly takes the entire program a step forward. Tesla has been hiring some employees for Robotaxi, but a vast majority of the job postings have been related to Vehicle Operator positions, meaning the people who are Safety Monitors or Validation Vehicle Drivers. Some job postings have hinted at Robotaxi expanding to new cities. However, on Tuesday, Tesla posted a new job for a Senior Insurance Claims Specialist, Robotaxi, the first of its kind. The job description says the employee will “oversee the company’s corporate insurance, risk management and surety programs across all business components.” Additionally, it says the position plays “a critical role in managing incident reporting a claim processes for Tesla Robotaxi and ride-hailing operations.” Buckle up — shit’s about to get real. Tesla hires Senior Robotaxi Insurance Claims Specialist. pic.twitter.com/RAdjJCYCeS — Tesla Yoda (@teslayoda) November 5, 2025 Essentially, Tesla could be looking to prepare for when it eventually will have to take liability for accidents completely. This would be when the company launches fully autonomous vehicles, meaning Cybercab and the Robotaxi program, specifically. It would also include passenger vehicles with Full Self-Driving. Tesla is currently operating a Robotaxi program in Austin, Texas, as well as a ride-hailing platform in the California Bay Area. These programs are the company’s first foray into ride-hailing, with or without someone in the driver’s seat of the vehicle. In Austin, Tesla operates most of its rides without a Safety Monitor in the driver’s seat. Only freeway routes require the Monitor to be directly behind the wheel. In California, someone sits in the driver’s seat at all times. The job posting seems to indicate that things could be relatively close in terms of solving self-driving, especially if Tesla is looking to fill a role that would handle autonomous insurance claims. Of course, it will take Tesla to solve autonomy, and with the company aiming to start Cybercab production (without a steering wheel) in Q2 2025, it surely feels like it is on the brink of something great. The post Tesla’s latest Robotaxi job posting takes the whole program a step forward appeared first on TESLARATI.

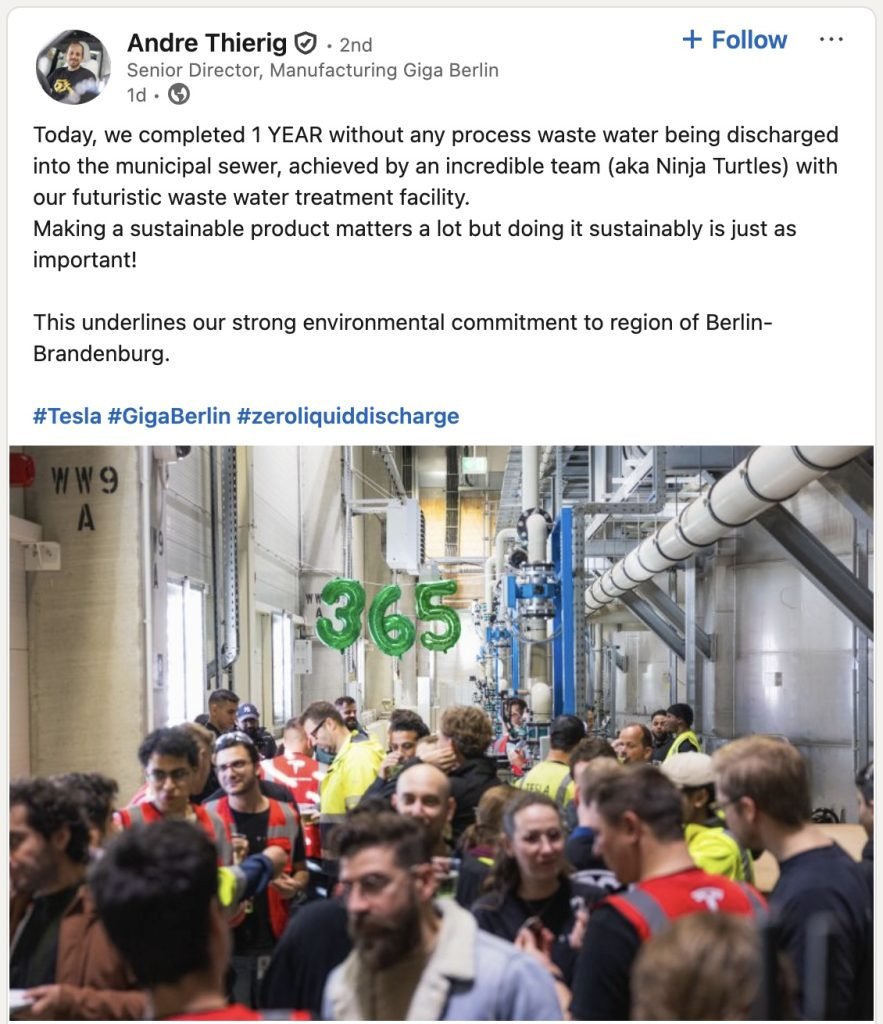

Tesla Giga Berlin hits a sustainability milestone that’s so impressive, it sounds fake

Tesla Gigafactory Berlin-Brandenburg has achieved a sustainability milestone that is so impressive, it almost sounds fake. As per the facility’s plant manager, Giga Berlin has completed one whole year without any of its process wastewater being discharged into the municipal sewer system. The announcement comes just over a month after Tesla Germany revealed that Gigafactory Berlin had returned 377,000 cubic meters of annual water rights to local authorities due to the facility’s sustainability systems. Insane one year feat Andre Thierig, Giga Berlin Senior Director of Manufacturing, stated that the factory’s one-year milestone was made possible by the facility’s industry-leading waste treatment systems. With no process wastewater discharged into the municipal sewer for a year now, Giga Berlin has effectively become one, if not the region’s, most environmentally friendly vehicle production facilities. “Today, we completed 1 YEAR without any process waste water being discharged into the municipal sewer, achieved by an incredible team (aka Ninja Turtles) with our futuristic waste water treatment facility. Making a sustainable product matters a lot but doing it sustainably is just as important! This underlines our strong environmental commitment to region of Berlin-Brandenburg,” the plant manager wrote in a LinkedIn post. Credit: Andre Thierig/LinkedIn Officials and Giga Berlin’s water consumption Jochem Freyer, Chairman of the Management Board of the Employment Agency Frankfurt (Oder), shared his congratulations to Tesla Germany. “The decision in favor of the facility was a strong move – for the environment, for the brand, for East Brandenburg! I hope for further innovations from Giga Berlin-Brandenburg, the official noted. In late September, reports emerged stating that Tesla Germany had returned 377,000 cubic meters of annual water rights to the Strausberg-Erkner Water Association (WSE). This was because the facility ended up using significantly less water than originally planned. WSE chairman Thomas Krieger stated that the water Giga Berlin was saving would be distributed to municipalities and other users in the region. The post Tesla Giga Berlin hits a sustainability milestone that’s so impressive, it sounds fake appeared first on TESLARATI.

Tesla Robotaxi and autonomy dreams lean on shareholders: Wedbush

Tesla’s dreams of developing a Robotaxi suite that utilizes a fully autonomous platform developed by the company’s top-tier talent now lean on shareholders and perhaps the most crucial vote in its history. That’s what Dan Ives of Wedbush said in a new note to investors on Wednesday. As the Annual Shareholders’ Meeting is now just one day away, investors are down to their final chance to vote for or against Elon Musk’s new compensation plan. Ives wrote that, while the company has made its intentions clear, wanting to maintain Musk, pay him accordingly, and give him the voting power he has long wanted, ultimately, the responsibility falls on investors. A new note from Wedbush’s Dan Ives on Tesla $TSLA: “A Big Day On Deck Tomorrow for Musk and Tesla; We Expect Pay Package Passes Tomorrow Tesla will be hosting its annual shareholder meeting with all focus on the Musk pay package on deck. We expect Musk to get overwhelming… — TESLARATI (@Teslarati) November 5, 2025 As many retail shareholders have pushed for people to vote for Musk’s compensation package, there are a handful of large-scale funds and firms that have decided to go in another direction. Bullish Wall Street firms, Wedbush being one of them, believe it is crucial for Tesla to maintain Musk. The vote could have major implications on whether Tesla launches an autonomous Robotaxi suite in the near future, Ives says: “Getting Musk’s pay package approved tomorrow at the highly anticipated meeting will be a big step towards advancing Tesla’s future goals with the autonomous and Robotaxi roadmap ahead.” While some investors are convinced the company is ready to go in a different direction simply based on Musk’s political involvement over the past year, many investors are under the impression that the development of Tesla’s autonomy suite, as well as its prowess in the EV sector, would fall if Elon were not at the helm. Tesla’s Board of Directors has already stated that they have received confirmation that Musk’s political involvement would wind down in a timely manner. Moving forward, his focus will not veer from the mission of any of his companies; at least that’s what can be gathered from some of the Board’s communications over the past month. Musk’s new compensation package is incentivized by performance metrics and will require him to achieve a handful of lofty tranches. He will not get paid unless he drives shareholder value, which is something many skeptics tend to leave out. Ives continues: “This new incentive-driven pay package for Musk would also provide an additional 423 million shares of common stock (~12% of shares), which would increase his ownership of Tesla up to ~25% voting power, which we believe was critical to keep Musk at the helm to lead Tesla through the most critical time in the company’s history. We believe this was the smart move by the Board to lay out these incentives/pay package at this key time as the biggest asset for Tesla is Musk…and with the AI Revolution, this is a crucial time for Tesla ahead with autonomous and robotics front and center.” Wedbush maintained its Outperform rating and $600 price target on shares. The post Tesla Robotaxi and autonomy dreams lean on shareholders: Wedbush appeared first on TESLARATI.

Tesla makes a splash at China’s Import Expo with Cybercab and Optimus

Tesla’s fully autonomous Cybercab made its first appearance in the Asia-Pacific region at the 8th China International Import Expo (CIIE) in Shanghai on November 5, becoming the centerpiece of an event that drew 12 of the world’s leading automakers. The new model offers a glimpse into Tesla’s driverless ride-hailing future, and based on the reception of the event’s attendees, it appears that Elon Musk’s vision is something that still resonates with people. Tesla showcases its driverless vision with the Cybercab At this year’s expo, themed “Mobility, Infinite Possibilities,” Tesla’s futuristic two-seat Cybercab stood out as a showcase of complete autonomy. According to Tesla staff, the vehicle lacks both a steering wheel and pedals, relying entirely on Tesla’s cameras and an end-to-end neural network designed for full self-driving. The Cybercab will ultimately serve in the company’s expanding Robotaxi fleet, a cornerstone of Elon Musk’s long-promised autonomous mobility network. During the event, a Tesla employee emphasized that the Cybercab’s model’s compact layout reflects real-world usage, as 92% of trips involve just one or two passengers, as noted in a Sina News report. Trips that require more passengers could easily be handled by the Model 3 and Model Y, which are both capable of seating four, or even five passengers. Optimus, Tesla’s humanoid robot that is designed for both home and industrial use, was also present at the event. Similar to the Cybercab, Optimus also attracted quite a lot of attention from the event’s attendees. $TSLA Tesla’s booth at the 2025 CIIE was swarmed by a sea of visitors today, just as anticipated pic.twitter.com/gJPMW2bPfZ — Ming (@tslaming) November 5, 2025 Automakers reaffirm commitment to Chinese innovation Other global automakers, including Volkswagen, Mercedes-Benz, and Honda, also displayed cutting-edge concept cars and intelligent systems, but few captured the same interest as Tesla’s bold showcase of its autonomy and robotics. Beyond new models, this year’s CIIE highlighted a renewed focus on local innovation and collaboration in China’s rapidly evolving EV landscape. Executives from Volkswagen, Audi, and General Motors reaffirmed that their long-term strategies center on “in China, for China,” strengthening R&D operations and forming tech partnerships with domestic suppliers. The post Tesla makes a splash at China’s Import Expo with Cybercab and Optimus appeared first on TESLARATI.

No ‘fireball squirrels’: Nature and next-generation data center design

The pipeline of U.S. data center construction projects has reached more than 500 sites and counting. With that boom comes a reckoning as communities in states from Wisconsin to Virginia scrutinize — and question — the heavy electricity, water and land requirements of what NVIDIA CEO Jensen Huang has dubbed “AI factories.” In early October, Microsoft retracted its plan to build on a site in Caledonia, Wisconsin, after local residents protested the potential conversion of agricultural land into an industrial site. The company will pursue development at another location in the state. “One of the pieces of feedback that we heard was that the parcel was too closely situated amongst other residents,” said Kaitlin Chuzi, director of integrated technology and biomimicry at Microsoft, during a recent Trellis Impact 25 discussion about how to include nature and biodiversity in data center development decisions. Engaging communities early is one of the best ways to address land-use questions and co-develop strategies for habitat restoration around new data centers or at other locations, according to the panelists. It starts with landowners and local officials who can connect companies with local conservation organizations to better understand community concerns. “Really listening to what they’re hearing is a really helpful way for us to develop an understanding but also ferment some of the ideas about which types of work would be most impactful for the community,” said Emily Backus, sustainability director for North America at Vantage Data Centers, which operates campuses for hyperscalers, cloud service providers and other companies with large data center needs. Another key stakeholder to include from “Day 0,” Backus said, are utilities. If a site requires new transmission lines, for example, that will dramatically increase the potential impact on nature and biodiversity. Part of the plan Data center companies such as Microsoft and Vantage have integrated habitat and biodiversity impact assessments and water studies into their standard design processes from the onset, especially as communities scrutinize a flood of data center site applications. Microsoft’s Chuzi, for example, reports to the company’s land management team; her role is not part of the sustainability office. Backus, on the other hand, collaborates closely with her company’s development engineers. While there’s no typical land use requirement for data centers — and operators are encouraging increasingly higher server densities — hyperscale facilities can still require 200 to 500 acres. Vantage uses unbuilt acreage to restore native habitats and encourage drought-resistant landscaping, eschewing turf or non-native plantings. By the end of 2024, it used this strategy at half of its site footprint, or about 4,000 acres. One of Microsoft’s climate goals, set in 2020, was to protect more land than its operational footprint requires by the end of 2025. It has already met that pledge, with more than 15,849 acres permanently protected, as of its latest environmental report. Biodiversity remains a focus amid its furious AI-related expansion phase. Biodiversity and ‘fireball squirrels’ Both Vantage and Microsoft embrace the philosophy of biodiversity net gain — the idea that development can make land more supportive for new species — to guide new projects. Vantage, for example, used rain gardens, vertical greenery and other nature-based features to manage stormwater at its MPX2 campus in Milan, Italy, and restore the local ecosystem. It also planted multiple species of trees and flowering meadows at the campus. Where possible, given construction codes, it adds green roofs to data center buildings. That could mean tradeoffs, however, from an emission standpoint, because more steel might be needed to support the weight of plants. Other tradeoffs include higher maintenance needs. “The big question that my team and I have been talking about recently is whether it is worth it to put a green roof data center or, for the same cost, do ecological restoration on 100 acres off site,” said Chuzi. Her preference would be to do both. Vantage will use a metric developed by consulting firm Ramboll to measure the impact of its North American projects, starting with two data centers in the Midwest. This was inspired by projects in the U.K., where demonstrating biodiversity net gain is mandatory for developers. This requires hiring ecologists who can perform initial and ongoing site evaluations. “You think about all those green spaces around your buildings and your parking lots,” Backus said. “All of those are opportunities to do really significant improvements that can improve the biodiversity of those areas.” Microsoft likewise looks for ways to add biological buffers and habitats to its campuses, a practice that was initially controversial with engineers, who were worried about squirrels and other rodents chewing through electrical lines. “They have so many valid reasons for why you can’t bring nature closer to the technology that we’re bringing to the site,” Chuzi said. “I think my favorite one, and maybe the most memorable excuse was, ‘Kaitlin, you can’t put plants near the data center because we’re going to end up with fireball squirrels.’” Much of Chuzi’s role involved balancing these concerns with biodiversity goals. The rodent problem, for example, can be addressed by encouraging habitat friendly to predatory birds that can help manage the population. A buffer can be established between plantings and crucial electric and transmission systems. And electrical systems can include additional insulation. “It’s a lot of pulling together opposing ideologies and changing how people think about technology, how they think about nature,” Chuzi said. Microsoft’s new AI trip mimics a leaf to distribute coolant.Source: Microsoft Innovation inspired by nature Nature is also reshaping design inside data centers. Concerns about water, for example, inspired both Microsoft and Vantage to prioritize the installation of “waterless” cooling equipment that relies on outside air to dissipate heat or closed-loop systems that retain and recycle water. Both companies are also looking for ways to funnel the heat generated by servers to places where it could be beneficial. Microsoft shares excess data center heat with a municipality in Finland, for example. That takes collaboration with neighboring sites, another reason community engagement is crucial for advancing data center

Okika launches Chameleon analog modules for flexible design

Okika Devices announced the launch of its new Chameleon product family, a compact analog module designed for a variety of analog design applications. Each Chameleon module integrates an Okika Field Programmable Analog Array (FPAA) with on-module nonvolatile memory, a precision oscillator, and reconfiguration circuitry, providing pre-programmed analog functions in a 14 × 11 mm LGA-32 form factor. Okika Chameleon Module. Designed for engineers who need analog flexibility without the complexity of firmware or digital control, Chameleon modules can operate as fixed-function analog blocks straight out of the box — no microcontroller required. Users can also reprogram configurations in-system or via a standard 3.3V SPI interface, enabling complete customization and rapid iteration. Key advantages Design Simplicity: Ships pre-programmed and ready to use — no microcontroller or firmware needed unless you want in-system reconfiguration. Custom Optimization: Okika provides application support and custom circuit configuration tailored to your performance goals. Compact Size: High-density interconnect (HDI) construction fits full analog subsystems into a 14 × 11 mm footprint. Standard Tools: Program using any 3.3 V SPI EEPROM programmer. Future-Proof Flexibility: Reconfigure analog functions — such as filters, amplifiers, PID loops, and oscillators — anytime, without new hardware. Built on FlexAnalog technology Each Chameleon module leverages Okika’s FlexAnalog FPAA architecture — a reconfigurable analog matrix featuring over 40 configurable analog modules (CAMs) including filters, amplifiers, oscillators, and more. Designers can simulate and verify performance instantly using Anadigm Designer 2 software with precise parameter tuning and filter design tools. Applications Programmable active filter networks Sensor signal conditioning and linearization Industrial automation and adaptive control Research and rapid prototyping For more information, visit okikadevices.com. The post Okika launches Chameleon analog modules for flexible design appeared first on Engineering.com.

EcoFlow early Black Friday Sale takes up to 80% off power stations from $75, exclusive new Mammotion robot lawn mower lows, more

Headlining today’s Green Deals is the EcoFlow early Black Friday Sale that is offering up to 80% discounts, with extra savings, free gifts, member-only pricing, and more. Among the lineup, we spotted the brand’s new DELTA 3 Max Portable Power Station getting a FREE TRAIL 200 DC power station at $759, with tons more great options for your backup power needs. Right behind that massive sale is a collection of eight exclusive deals that are offering up to $1,050 savings on Mammotion Robot Lawn Mowers at new lows starting from $699. We also have EcoFlow’s first early Black Friday 48-hour flash sale, as well as EGO’s heavy-duty 56V 24-inch two-stage snow blower kit, and more waiting for you below. And don’t forget about the hangover deals that are collected together at the bottom of the page, like yesterday’s early Black Friday e-bike sales from Lectric and Heybike, and more. Head below for other New Green Deals we’ve found today and, of course, Electrek’s best EV buying and leasing deals. Also, check out the new Electrek Tesla Shop for the best deals on Tesla accessories. more…

2026 Polestar 4 electric ‘SUV coupe’: competent, confusing, lacks one component

The 2026 Polestar 4 is an unusual vehicle, even for an EV from Sino-Swedish startup brand Polestar. Its makers call it an “electric performance SUV coupe”, though it has four doors. It’s smaller than the Polestar 3 SUV, though larger than the Polestar 2 compact crossover—meaning the Polestar lineup, from small to large and cheapest to priciest, runs from 2 to 4 to 3. Its most notable feature may be its lack of a rear window; the trunk lid ends at the visual base of the roof. We worry all this makes it a confusing model that may be a challenge to sell: It’s an unusual body style, from a largely unknown brand, that’s missing a large and obvious component shoppers expect in every new vehicle. The Polestar 4 has been on sale since August as a 2026 model; first deliveries are expected before the end of the year. US and Canadian cars are made in Busan, South Korea, the second assembly plant to assemble the P4 after Hangzhou Bay, China. Battery cells for those Busan models still come from CATL in China, however. Note the pre-production 2025 models we drove in Montreal in July differed slightly from US-market 2026 Polestar 4s. The Long Range Single Motor model is EPA-rated at up to 310 miles of range, starting at $57,600, while the pricier but faster Dual Motor version takes a slight hit down to 280 miles. For those customers keeping track, the company notes the 4 has the lowest lifetime carbon footprint of any Polestar to date. A design difference no customer asked for? Let’s deal with the lack of a rear window right up front. Why did Polestar do it, aside from echoing a concept car from back in 2020? Executives spoke at some length about how eliminating a glass rear window permitted a sleeker, more sloped fastback tail and a lower roofline, while still providing the necessary rear headroom. We’re not convinced. The lack is far more noticeable in light colors, less so in darker ones. The glass roof has been visually extended to the top of the trunk lid with shiny black plastic panels. Still, we couldn’t help but notice an indent in the tall trunk lid that might provide a cut-out for at least a vestigial rear glass—if customers bridle at its lack. Alternatively, perhaps this reporter simply isn’t the right audience for the car. The woven interior fabrics, known as Tailored Knit upholstery, are made entirely from recycled PET, with the fabric knitted to size. The part of the dash facing the occupants, covered in this woven fabric, is elegant—but the effect is spoiled by a black nylon mesh further up toward the windscreen, which both of us agreed looked and felt cheap. We appreciated the distinctive pop of colour in the seat belts, either an orange stripe on black or solid orange. Fast but firm … to harsh Polestar notes the 4 is its fastest model to date, with the highest-performance mode of its Dual Motor version taking just 3.7 seconds to accelerate from 0 to 60 mph. That model is quoted at 405 kilowatts (544 horsepower) and 506 foot-pounds of torque. The rear-wheel-drive Single Motor variant is quoted at 200 kW (272 hp) and 253 lb-ft of torque, with 0-6o-60-mph acceleration of 6.9 seconds—almost double that of the hot-rod version. Both are powered by a 100-kilowatt-hour battery pack (94 kWh usable) with cells from China’s Contemporary Amperex Technology Co. Limited (CATL). Fast charging speed is quoted at up to 200 kilowatts. Behind the wheel, acceleration is clearly there when called for. I might have liked a bit more steering feel, though the car goes where it’s pointed just fine. Among the available performance options are active dampers (shock absorbers) and 4-piston Brembo brakes. The handling and roadholding are on the heavy side, and in corners you can feel the tires working to hold this 5,200-pound vehicle in place. Even on the Normal suspension setting, the ride is notably firm; we managed to hit the bump stops, quite unintentionally, while going through one pothole. The sportier settings head into rougher-ride territory. Polestar’s implementation of one-pedal driving does not slow the car entirely. Below about 5 mph, the driver must brake to a stop. Its regenerative braking, even on the strongest setting, is on the gentle side compared to other EVs, though easy to learn and plan for. Then there’s the challenge of the video rear-view mirror (since a regular glass mirror has no view through a rear window to reflect). The windshield is so steeply raked that the mirror is surprisingly close to the driver’s eyes, making it a challenge to switch focal distance from a few hundred feet ahead to perhaps 18 inches, then back again. Plus, the image squirms in the corner of the driver’s eyes, and it moves sideways when a turn is signaled. My driving partner said his eyes felt tired from the continual refocusing, and even a Polestar exec admitted it had taken him three days to acclimatize to that aspect of the car. To its credit, Polestar uses very good rear-view cameras, and the backup image was superb. Quiet, well-bolstered, screen-centric The low “coupe” roofline combined with the underfloor battery pack means all occupants, including those in front, sit in a slightly knees-up posture. This is hardly unique to the P4, but it remained noticeable even after moving the driver’s seat as high as it would go—more so than in the P2 or P3 with their more upright SUV proportions. Seats were comfortable and well bolstered, as buyers expect in a performance-oriented EV. We heard no noise at all from the motor or power electronics, and very little wind noise. The bulk of the sound that entered the cabin was tire noise from the 22-inch wheels on our test car (20- and 21-inch wheels are also available). We were amused to find the classy indicator “tick” noise broadcasts on the left-hand speaker for a left turn, but

Tesla investors are ditching Charles Schwab after its vote against Musk comp plan

Tesla investors are ditching Charles Schwab as their brokerage after the firm said earlier this week that it would vote against CEO Elon Musk’s new compensation package. Several high-profile Tesla influencers are speaking out against Charles Schwab, saying its decision to vote against the plan that would retain Musk as CEO and give him potentially more voting power if he can achieve the tranches set by the company’s Board of Directors. The Tesla community recognized that Schwab is one firm that tends to vote against Musk’s compensation plans, as they also voted against the CEO’s 2018 pay package, which was passed by shareholders but then denied by a Delaware Chancery Court. Schwab’s move was recognized by investors within the Tesla community and now they are speaking out about it: Hey @CharlesSchwab – I need to speak with someone from Schwab Private Wealth Services this week. Please reach out via email, the mobile app message center, phone, or X DM. Here’s why this is urgent: At least 6 of your ETF funds (around 7 million $TSLA shares) voted against… — Jason DeBolt (@jasondebolt) November 3, 2025 If @CharlesSchwab doesn’t vote for Elon Musk’s 2025 CEO Performance Award plan, I’ll move all my assets to another brokerage. My followers, many of whom also hold assets with Schwab and collectively own at least hundreds of millions in $TSLA, may do the same. I can’t in good… — Sawyer Merritt (@SawyerMerritt) November 3, 2025 ready to help with the @CharlesSchwab exodus — Gali (@Gfilche) November 3, 2025 At least six of Charles Schwab’s ETFs have voted against Tesla’s Board recommendation to support the compensation plan for Musk. The six ETFs represent around 7 million Tesla $TSLA shares. Jason DeBolt, an all-in Tesla shareholder, summarized the firm’s decision really well: “As a custodian of ETF shares, your fiduciary duty is to vote in shareholders’ best interests. For a board that has delivered extraordinary returns, voting against their recommendations doesn’t align with retail investors, Tesla employees, or the leadership we invested to support. If Schwab’s proxy voting policies don’t reflect shareholder interests, my followers and I will move our collective tens of millions in $TSLA shares (or possibly hundreds of millions) to a broker that does, via account transfer as soon as this week.” Tesla shareholders will vote on Musk’s pay package on Thursday at the Annual Shareholders Meeting in Austin, Texas. It seems more likely than not that it will pass, but investors have made it clear they want a decisive victory, as it could clear the path for any issues with shareholder lawsuits in the future, as it did with Musk’s past pay package. The post Tesla investors are ditching Charles Schwab after its vote against Musk comp plan appeared first on TESLARATI.