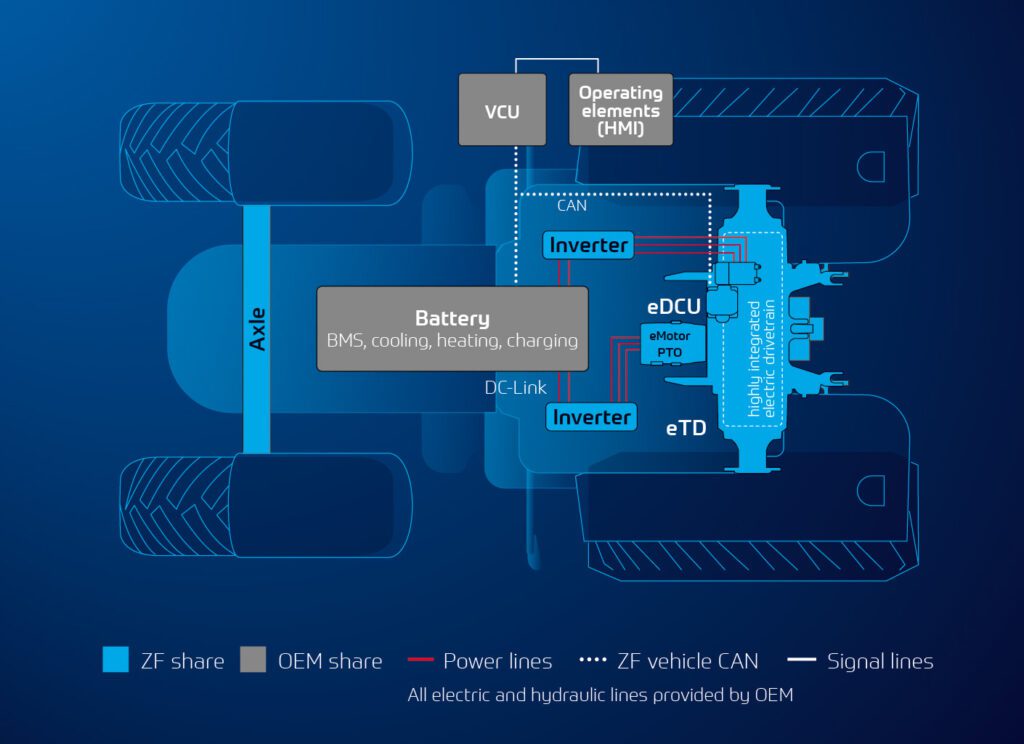

ZF has announced its eTERRADRIVE, a modular and highly integrated electric transaxle system designed for battery-electric vehicle architectures in agricultural tractors ranging from 60 to 100 kW.

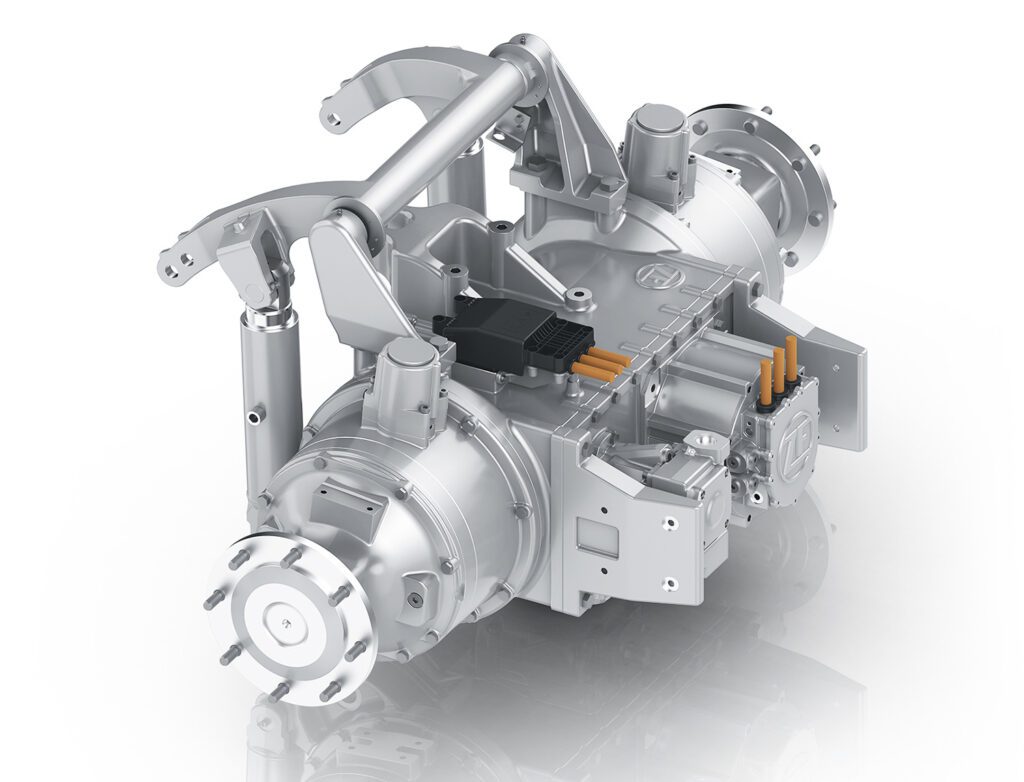

This system combines traction, mechanical power take-offs, working hydraulics and rear lift within a single compact unit, aiming to facilitate integration and flexibility across a variety of tractor platforms and track widths.

ZF says the eTERRADRIVE’s compact design allows for maximum installation flexibility, enabling applications not only in specialty crop operations but also in municipal and conventional farming. The system is fully compatible with current tractor-implement mechanical interfaces, allowing for easier retrofit and adoption into existing machine concepts.

eTERRADRIVE incorporates two oil-cooled synchronous motors and an integrated planetary gear set. ZF says this results in greater operational efficiency, precise torque management and optimized energy use compared to conventional hydrostatic continuously variable transmission (CVT) electrification approaches, which typically replace an internal combustion engine with an electric motor but introduce higher mechanical complexity and losses.

The architecture also enables full energy recuperation at all performance levels and introduces switchable auxiliary systems for improved energy efficiency. The electronic control architecture features a stand-alone control unit, the eDCU, which communicates with tractor control units and vehicle domain controllers.

ZF says that by consolidating driveline, the eTERRADRIVE opens up more space for larger onboard energy storage—such as batteries or hydrogen tanks—enabling extended zero-emission operation without compromising full working functionality.

Source: ZF

Topics: ZF, Electric Motors, Power Electronics