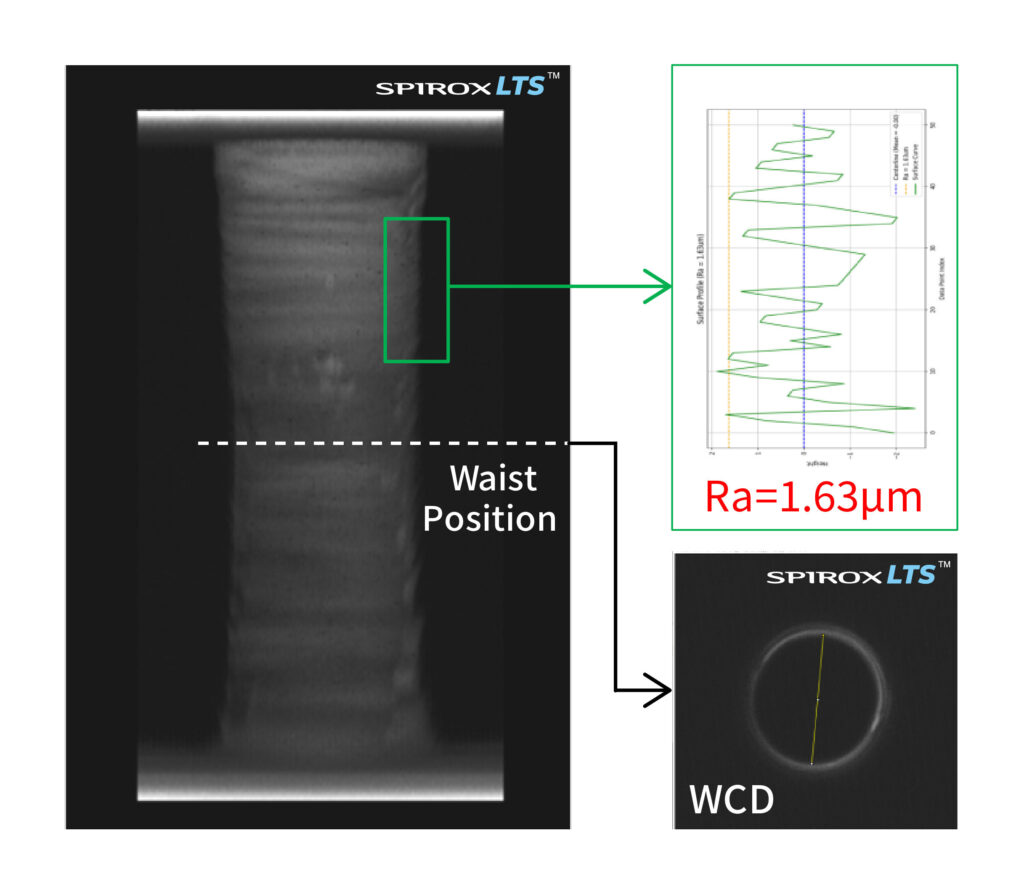

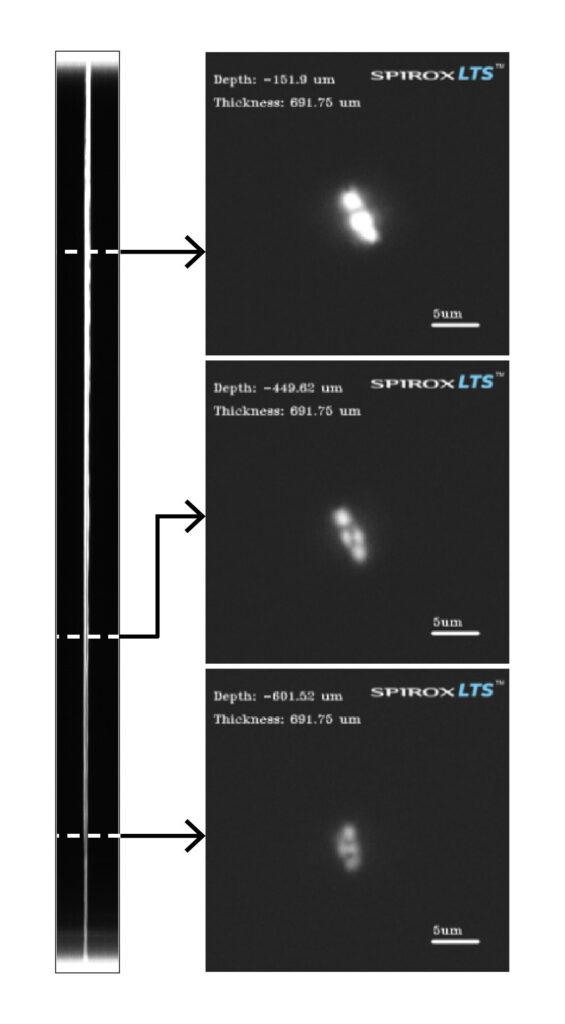

Spirox Corporation, a semiconductor equipment provider, has introduced SpiroxLTS (Spirox Laser Tomography Scanning) technology. This new system uses a combination of patented nonlinear optical integration methods to enable non-destructive, contact-free imaging of laser-modified cross-sections within through glass vias (TGV). SpiroxLTS allows for detailed visualization of modification continuity and uniformity in glass, supporting process quality checks and providing data to help optimize TGV fabrication parameters and production efficiency.

As high-performance computing (HPC), high-frequency communications, AI accelerators, and high-performance servers continue to evolve, through glass via (TGV) technology is increasingly used in advanced packaging. TGV provides a low dielectric constant, thermal stability, and supports high-density I/O integration, making it suitable for glass core substrates and 2.5D/3D interposer architectures. Demand for TGV is growing, but monitoring laser modification quality during early processing stages remains difficult. This presents challenges for managing yield and controlling costs, particularly when switching between different glass types.

Hi-Nano Optoelectronics, which has experience in TGV laser process materials and technology development, recognizes the potential of SpiroxLTS to support data-informed and visual laser processing. The company sees it as a useful platform for materials research and process optimization. Hi-Nano and Spirox’s complementary areas of focus may support future collaboration in development and production.

SpiroxLTS technology provides a way to visualize laser-modified layers within glass, supporting the development of glass core products. It replaces traditional destructive inspection methods with a non-destructive approach, helping manufacturers reduce development time and better assess modification consistency.

According to manufacturers involved in metallization and build-up processes for TGV packaging substrates, back-end production stages require precise via structures and consistent laser modification. Previously, limited inspection data made it difficult to detect issues early in the process. SpiroxLTS, verified through testing, offers non-destructive inspection capabilities that allow quality checks to begin during materials verification and process validation. This approach supports more consistent production of TGV substrates used in advanced packaging.

For more information, visit spirox.com.tw.

The post SpiroxLTS enables imaging of laser-modified TGV structures appeared first on Engineering.com.