At automatica, Siemens announced plans to integrate its Operations Copilot into driverless transport systems and mobile robots. The Operations Copilot is designed to support machine operation and maintenance. As mobile transport robots increasingly function as autonomous agents using artificial intelligence (AI), the Copilot will provide an interface for users to configure autonomous mobile robots (AMRs) and automated guided vehicles (AGVs), assigning them tasks such as moving materials across the shop floor. This step contributes to broader efforts to enhance factory automation using generative AI.

Operations Copilot will be enhanced with agents for AMRs and AGVs

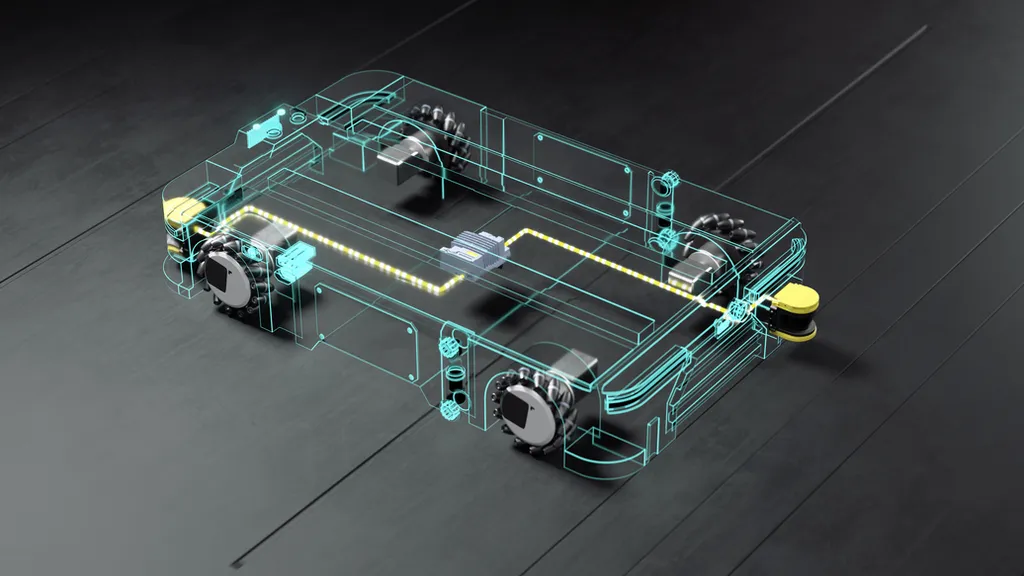

Siemens plans to enhance the Operations Copilot with AI agents designed for automated mobile robots (AMRs) and automated guided vehicles (AGVs). These agents will assist with both commissioning and operation of individual units and fleets. Commissioning AGVs can be complex, requiring integration with a factory’s existing IT and OT systems and configuration for specific conditions such as routes and transfer stations. To simplify this, the Operations Copilot uses AGV sensors and cameras to build a detailed view of the environment. It can also access technical documentation and real-time system data through its interface, helping engineers and operators work more efficiently and deploy systems more quickly.

New Safe Velocity software enhances safety on the shop floor

AGVs use navigation and sensor technologies to operate safely in production and logistics settings without direct human control. They respond to obstacles by slowing down, stopping, or rerouting. Siemens’ Safe Velocity software enables fail-safe vehicle speed monitoring, allowing safety laser scanner fields to adjust dynamically in real time. TÜV-certified and compatible with various AGV platforms, the software supports compliance with industrial safety standards. Safe Velocity can reduce the need for extra safety hardware, helping simplify system design, save space, lower engineering effort, and reduce cabling—while maintaining functional safety.

In future implementations, the Operations Copilot will work with AI agents like Safe Velocity to analyze data from safety laser scanners and monitor AGV speed. The Safe Velocity agent oversees autonomous vehicle operations and can coordinate with other agents developed for AGV and AMR use cases. This approach supports the development of a multi-agent system, where the Operations Copilot manages both physical and virtual agents to improve coordination between digital systems and real-world operations.

For more information, visit siemens.com.

The post Siemens advances autonomous production with new AI and robotics capabilities appeared first on Engineering.com.