QuesTek Innovations has added titanium alloy modeling capabilities to its ICMD (Integrated Computational Materials Design) software platform. This update expands the platform’s functionality, supporting materials engineers with deeper insight into the behavior of Ti alloys in sectors such as aerospace, energy, and additive manufacturing. ICMD is a cloud-based platform developed to help reduce risk and support efficient materials development from concept through qualification.

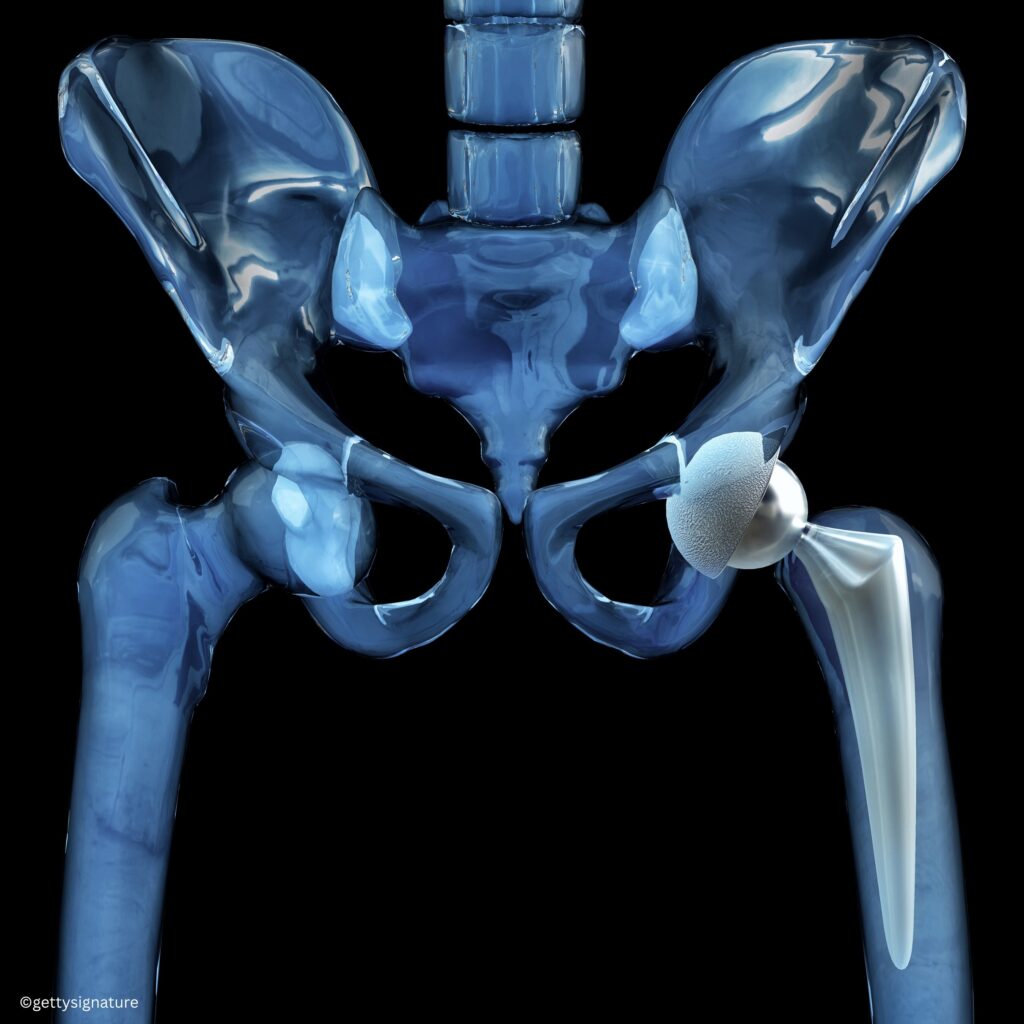

Titanium is widely used in aerospace components and orthopedic implants due to its strength, fatigue resistance, and biocompatibility. ICMD supports the data-driven design of titanium alloys to address these performance requirements.

Expanded property modeling tools for Ti alloys

The latest ICMD release adds models to estimate mechanical properties of Ti-based alloys—such as elastic modulus, shear modulus, Poisson’s ratio, yield strength, and tensile strength—based on alloy composition and processing data. These tools support early-stage alloy screening and optimization, helping reduce the need for extensive physical testing.

Simulating heat treatment effects on microstructure

The update includes process-structure models that simulate the impact of heat treatment on alpha-phase development. Users can model the coarsening of alpha laths and the formation of globular alpha during annealing, supporting the design of microstructures with targeted strength, ductility, and fatigue resistance.

Supporting better additive manufacturing outcomes

Another enhancement provides predictive modeling of dendritic grain morphology under different solidification conditions. This helps engineers anticipate whether a material will form columnar or equiaxed grains, enabling alloy and process designs that reduce anisotropy and improve part performance—particularly for 3D-printed components.

These updates further strengthen ICMD as a comprehensive platform for materials innovation and qualification, giving users control over microstructure-driven performance outcomes in demanding applications.

For more information, visit questek.com.

The post QuesTek expands ICMD with titanium alloy modeling capabilities appeared first on Engineering.com.