I traded my ICE vehicle for a Tesla Model Y: here’s how it went

I recently decided, after a variety of things, that I was going to trade in my internal combustion engine (ICE) vehicle for a new Tesla Model Y. It was a long time coming. After working at Teslarati for six years and covering the EV space nearly every single day (I recently published my 5,000th article on here), I figured it was time to make a switch. Over the past few years, there have been days when I would have been better off with an EV, but my Summer and Winter activities, as well as the price, kept me from making the switch. Recently, I decided that it was time. My 2021 Ford Bronco Sport had been experiencing a number of issues, none major, but numerous sensor replacements. It was an affordable and fun car, but after fixing the Tire Pressure Monitoring System in the front right tire, an EVAP switch valve in the motor two months ago, and some other things, the Bronco became more of a chore (and a drain on my wallet) than anything. With the timing of the $7,500 tax credit expiring and a substantial amount of positive equity in my Bronco, I knew it was time. My experience was excellent, but I would like to share some insights with our readers about the entire process, which may also help you make the jump. Others were more of a one-time thing, as they were things customers would only deal with as the tax credit went away. My Decision I knew I was going to get a Tesla, and my inability to enjoy a good sedan steered me to a Model Y (no hate toward the Model 3, it’s just not for me). I knew with the weather in Pennsylvania, all-wheel drive was a need, and the price difference between the rear-wheel-drive and AWD configurations of the Y made it a no-brainer. Plus, I really would like to get this thing out on the beach, something I’ve done every Summer since buying the Bronco with my Fiancè. COME WITH ME TO TRADE MY ICE VEHICLE FOR A NEW TESLA MODEL Y — TESLARATI (@Teslarati) August 30, 2025 I actually ordered this car back in June, but ended up canceling the reservation to wait until the end of Summer. I ended up ordering the car I took delivery of on Saturday back on my birthday on August 16. I was looking for Diamond Black with White Interior, and it was available in Pittsburgh for delivery. However, I really love the team at Tesla Mechanicsburg, so I opted to do a Black on Black Model Y that was a Fremont build, so I could pick it up from the guys up there. The interior color was not a dealbreaker for me. I just wanted to take delivery soon. I ordered from inventory, which is not something that is possible now. There is no new Model Y inventory within 200 miles of me, a good sign for Tesla but a bad sign if you’re looking to buy something before the quarter ends. Luckily, the IRS is allowing people to enter an agreement for a car, so you could technically build the car of your choice, put a down payment on it, and take delivery after the September 30 cutoff. Tesla Delivery Day My appointment was at 12 p.m. and I arrived about ten minutes before. The team greeted me quickly, and I was able to walk right up and see my car with my name on it. It was pretty incredible and a feeling I have not felt in a long time. I’ll be honest, when I bought the Bronco, I never thought I’d own one. When I got one, it felt pretty surreal. I felt that way yesterday. It was really cool to finally buy a car that I’d only dreamed of owning. It’s not the only car I dream of owning in my lifetime, but it is one I knew I wanted right now. Now that I was showing up to buy it, it really felt surreal. The process was really fast and efficient, and I could have been in and out in ten minutes if I wanted to. However, I hung around and talked to the guys there; they discussed some good accessories I should consider and suggested some tint. I was on my way. My First Drive and What to Expect I stopped by my Fiancè’s work, showed her the new ride, brought her some lunch, and headed home to my pup. So far, I’ve driven about 60 miles, with most of it being done manually and about 10 miles using Full Self-Driving. I’ve enjoyed driving it myself so much as of right now, but I know FSD will come in handy plenty in the coming months. My brand new ride! Thank you @tesla @elonmusk for building one badass car pic.twitter.com/jzpMawmTZs — Joey Klender (@KlenderJoey) August 30, 2025 In the future, I plan to explore a wide range of topics as an owner. I do not currently have home charging, which is something that many people believe is a dealbreaker for owning an EV. I have two Superchargers very close to my place, so I’m not too concerned about it. I have been in touch with my leasing office about installing a charger or chargers for the past few months, which seems like it could happen early next year. So far, I’m really happy with how everything has worked out. The post I traded my ICE vehicle for a Tesla Model Y: here’s how it went appeared first on TESLARATI.

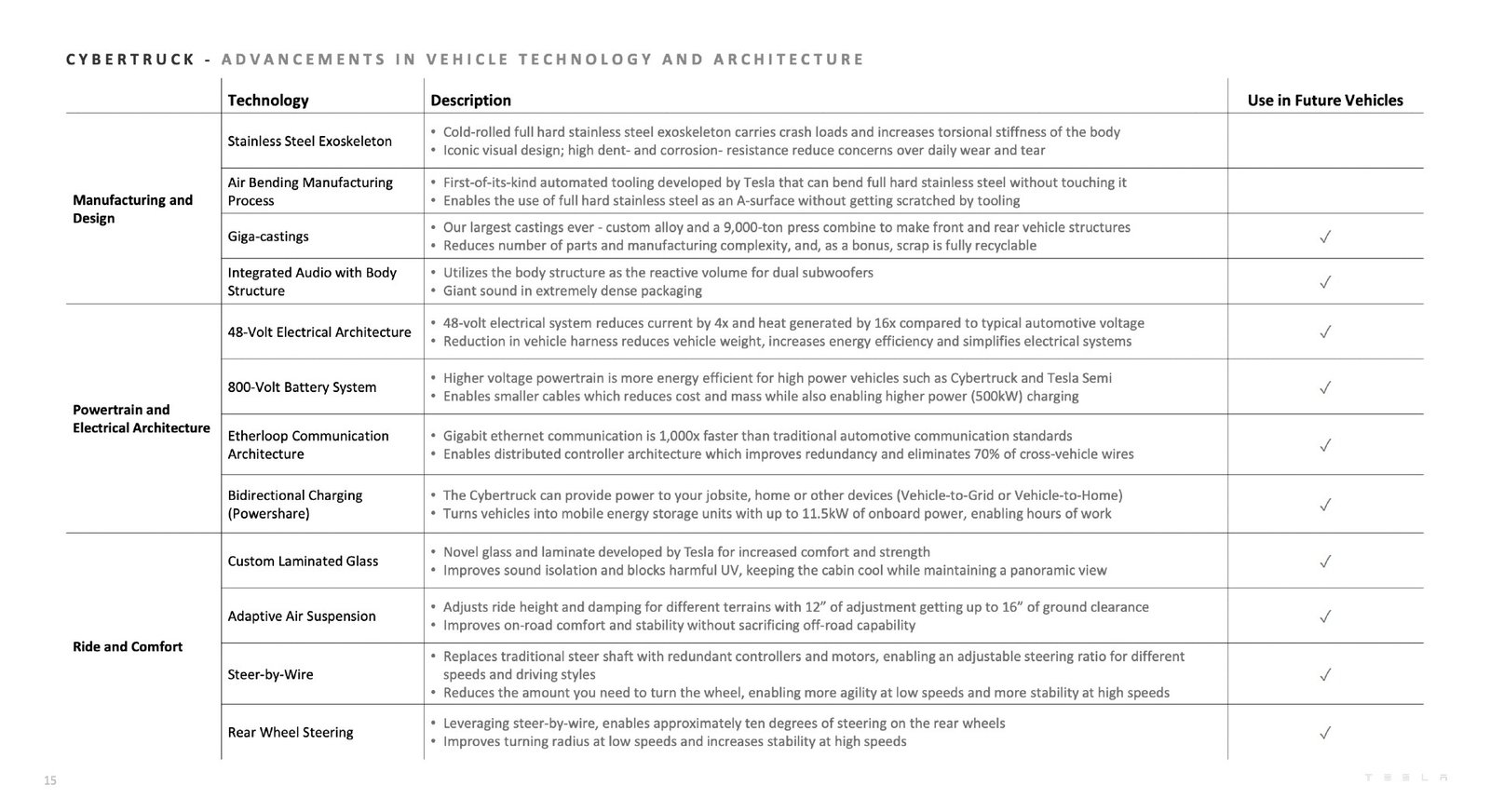

Tesla appears to be mulling a Cyber SUV design

Tesla appears to be mulling a Cyber SUV design, which would encapsulate the stainless steel exoskeleton of the Cybertruck but with elements of an SUV. The company has been hearing from consumers and fans for some time that it is in need of a full-size SUV in its lineup. Tesla is missing one type of vehicle in its lineup and fans want it fast The Model X is more compact than what people are looking for, and although the company has said its focus for some time would be on developing affordable models and the Cybercab, which only enables two-passenger travel, it appears that it may be considering other options. In a new video titled “Sustainable Abundance,” Tesla was showing the Cybercab clay models being autonomously molded. In the back, there are very clearly several models of a Cybertruck-inspired SUV: BREAKING: Tesla has revealed a Cyber SUV model in their new “Sustainable Abundance” video. The mini models can be seen in the back of the Tesla design studio behind the clay Cybercab in the video. Whether Tesla will release a Cyber SUV remains to be seen, but based on these… pic.twitter.com/tEhckWBHvC — Sawyer Merritt (@SawyerMerritt) September 1, 2025 This would not be the first time Tesla has placed projects it is developing in the back of a promotional video, as it did something similar when it was unveiling the improvements it made to the new Model Y earlier this year. It appeared to show two new body styles sitting in the back under car covers: View this post on Instagram A post shared by TESLARATI (@teslarati) There are two things that could prevent this from becoming a future, developed product that reaches the market. One of them seems to be a definitive no, but Tesla’s plans could certainly change, especially given the strong push from fans for this type of vehicle. Tesla said it wouldn’t build a Stainless Steel exoskeleton vehicle again Tesla said in its Q4 2024 Shareholder Deck that Cybertruck’s stainless steel exoskeleton would not be used in future vehicles in the top line: This seems like a definitive no in terms of developing an SUV based on Cybertruck’s aesthetics. However, that could always change. Tesla’s main focus in autonomy currently Developing an SUV of this size has been previously dismissed by Tesla, as its focus is on autonomy, AI, and robotics. However, it will still need to develop attractive and useful vehicles that address a large market, and the United States has a strong affinity for SUVs and crossovers. It seems totally feasible that Tesla could bring this type of vehicle to market to appease the many fans who have called for the company to build it. Tesla has not committed to anything at this point, which is the most important thing to remember. The post Tesla appears to be mulling a Cyber SUV design appeared first on TESLARATI.

Tesla receives European Ecolabel (EMAS) seal for Giga Berlin-Brandenburg

Tesla has been awarded the European Ecolabel (EMAS) seal for Gigafactory Berlin-Brandenburg. The EMAS seal highlights Tesla’s existing environmental measures in the facility, such as extensive reforestation efforts and reduced water usage. It also emphasizes Tesla’s commitment to improve its environmental initiatives. Giga Berlin’s environmental initiatives The EMAS (Eco-Management and Audit Scheme) seal is a long-term environmental management system that focuses on compliance with regulations and improving environmental performance, as noted in a Tagesspiegel report. Plant manager André Thierig noted that Tesla has already planted over 2 million trees to replace the trees that have been felled to make way for Giga Berlin. Tesla is also targeting an additional 5 to 15 MW peak solar capacity this year to make the plant more sustainable. “We will continue to promote photovoltaics in the future,” he said. Giga Berlin’s consumption and energy use In 2024, Giga Berlin consumed about 419,503 MWh of energy, with electricity accounting for more than half, followed by natural gas. The facility is looking to lower natural gas use by redirecting the use of process heating water via waste heat. Water consumption was listed at 2.16 cubic meters per vehicle, significantly below the industry average of 3.5. This year, Tesla Giga Berlin is looking to recycle 90% of the Model Y plant’s process wastewater. Around 11,000 employees currently work at Giga Berlin, which produces 5,000 vehicles per week or roughly 250,000 units annually. Tesla Grünheide erhält EMAS-Umweltsiegel! Die Fabrik setzt auf mehr Solarenergie (15 MWp 2024), spart Wasser (2,16 m³/Fahrzeug) und reduziert CO2 (39.667 t). Über 2 Mio. Bäume wurden aufgeforstet, weitere folgen. Energieverbrauch sinkt, Recyclingquote steigt auf 90 %.… pic.twitter.com/JTMSE4PYiG — Mirco Colditz (@ColditzMirco) September 1, 2025 Certification welcomed but not without criticism The EMAS program requires companies to disclose resource use, emissions, and improvement plans. Over 40 companies in Brandenburg have EMAS certification. Brandenburg’s Environment Minister Minister Hanka Mittelstädt (SPD) described Tesla as a role model for the region. “Everything is public, and that also creates a certain amount of trust,” she said, noting that Tesla is a “beacon” in the industry. Monique Zweig, Managing Director of the East Brandenburg Chamber of Industry and Commerce (IHK), shared her optimism in a comment to rbb24. “At Tesla, you can see that climate goals go hand in hand with industry,” Zweig stated. Unsurprisingly, local activists expressed skepticism. The Association for Nature and Landscape in Brandenburg, which is against Tesla, questioned whether the certification could be used as “greenwashing.” The group also alleged that the certificate could pave the way for weaker oversight for the EV maker. “The seal is ‘greenwashing’ to portray the company as more environmentally friendly,” spokesperson Steffen Schorcht noted. The post Tesla receives European Ecolabel (EMAS) seal for Giga Berlin-Brandenburg appeared first on TESLARATI.

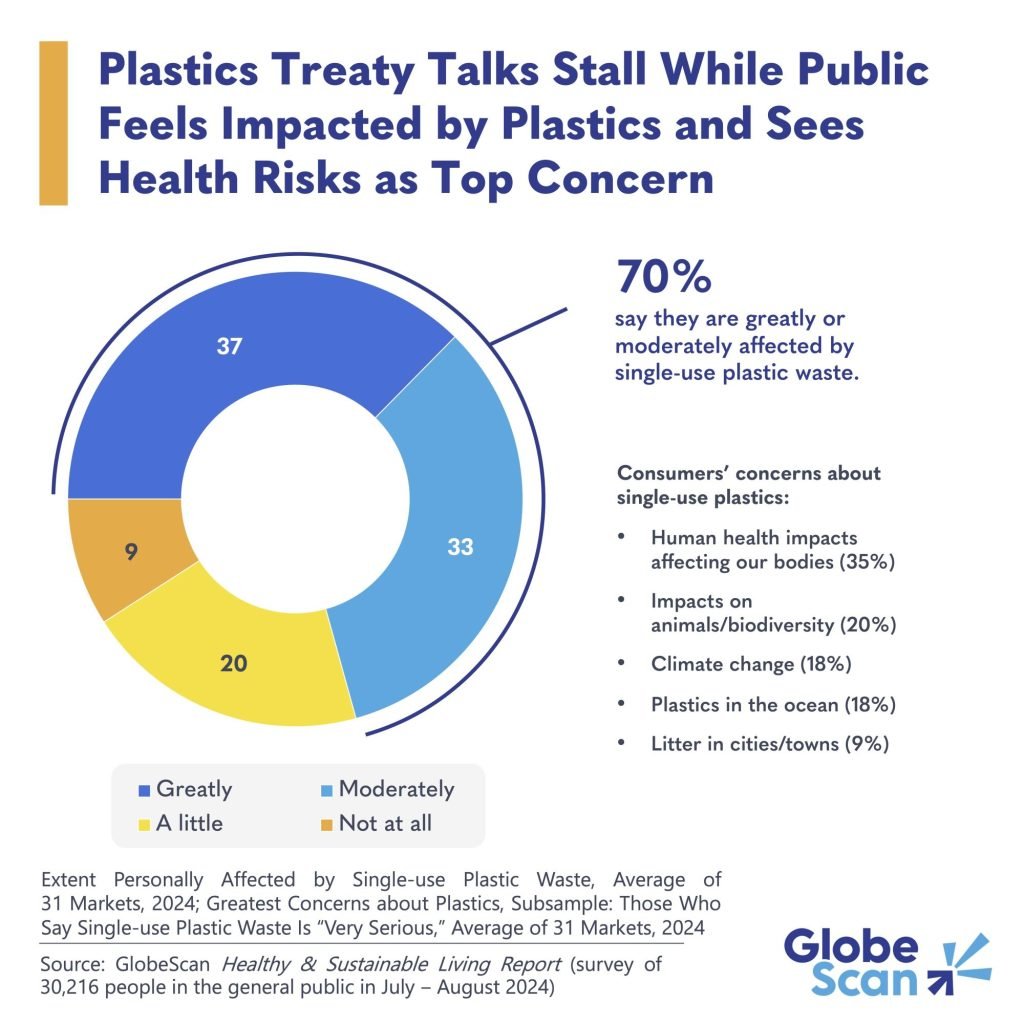

Global policy progress on plastics stalls, despite public concern

Despite growing concerns over plastic pollution and how it’s affecting human health, global policy progress on the matter is faltering. Research from Trellis data partner GlobeScan, in conjunction with ERM and Volans, shows that sustainability experts ranked a Global Plastics Treaty as highly impactful but among the least feasible actions out of 64 sustainability measures assessed. While the research was conducted prior to the latest treaty negotiations, treaty talks have stalled without meaningful commitments. The unlikelihood of a treaty is all the more pressing at a time when public concern over plastic pollution is widespread. A Globescan study from last year showed 70 percent of people globally felt directly impacted by single-use plastic waste. The leading concern of single-use plastic waste? Not climate change or ocean pollution, but the presence and effect of microplastics and chemicals in the human body. What this means The gap between the low feasibility of a global treaty and the significant public concern over the health impacts of plastics presents both risk and opportunity for business. Brands that take decisive action to reduce plastics can build consumer trust and credibility, while those that delay may face reputational challenges with increasingly health-conscious audiences. Based on a survey of 844 sustainability practitioners in 72 countries conducted April-May 2025 and an online survey of more than 30,000 people across 31 markets conducted in 2024. The post Global policy progress on plastics stalls, despite public concern appeared first on Trellis.

Xpanner launches X1 Kit for construction sites

Xpanner introduced X1 Kit, a scalable Physical AI-based retrofit solution for construction site automation. The kit addresses challenges such as labor shortages, safety risks, and operational inefficiencies with a flexible, equipment-agnostic system that can be integrated into existing construction machinery. Since its formation in South Korea in 2020, Xpanner has been at the forefront of advancing construction technology. Founded by industry experts Henri Lee, David Shin, and Ryan Park, the company expanded to the U.S. in 2023 with a goal to transform cutting-edge technology into something tangible and beneficial for operators on the ground. They inaugurated this expansion with their automation-ready package, which offers construction equipment like the Orteco Pile Driver and Develon Excavator, pre-configured with automation-enhancing features—such as remote control, smart attachments (tiltrotator), and precision guidance systems. X1 further solidifies their vision, integrating Physical AI capabilities to transform existing construction machines across all brands and models into intelligent Software-Defined Machinery (SDM). Xpanner’s current customers had exclusive access to X1 and are using the technology in forward deployments. X1 is officially available on the market and its designed for immediate field readiness. It can currently be used across a range of construction applications’ deployed on pile drivers, with plans underway to extend its use to additional machinery. X1 is used in applications such as pile driving for solar installations. It is designed to automate complex tasks, reducing the need for highly skilled labor while lowering costs and improving efficiency. In a recent piling project, the system reduced labor requirements by 80% and operation time by 50%. The system also incorporates adaptive capabilities, allowing it to improve performance over time on the jobsite. Key to X1’s operation is a triad of Xpanner’s advanced technologies: Mango, M2, and a proprietary software suite. Mango, a hardware control marvel, facilitates highly precise machine operations, while M2 processes environmental data to strategize and transmit real-time operational commands. Accompanying these modules is a centralized platform that manages seamless integration and user interactions, enhancing oversight and optimizing workflow through continuous remote updates. For more information, visit xpanner.com. The post Xpanner launches X1 Kit for construction sites appeared first on Engineering.com.

After e-bike fury, suburban pearl-clutchers set their ire on golf carts

First, it was e-bikes, offering an efficient, effective, and low-cost way for teens and just about everyone to zip around town, yet drawing the temper of suburban traditionalists. Now golf carts are the new public enemy number one in suburbia, at least if you ask the growing number of online groups where residents complain about these small electric vehicles “clogging” their streets. But beyond the hand-wringing, golf carts and their more sophisticated cousins known as Neighborhood Electric Vehicles (NEVs) or Low Speed Vehicles (LSVs), are quietly becoming a popular alternative to cars for short trips around US cities and suburbs. more…

ChargePoint and Eaton launch V2X-capable EV fleet charging system

EV charging provider ChargePoint and intelligent power management company Eaton have announced a new “ultrafast charging architecture with end-to-end power infrastructure for public charging and fleets.” ChargePoint Express Grid, powered by Eaton, is a vehicle-to-everything-capable system that can deliver up to 600 kW of power for passenger EVs and megawatt charging (1,000 kW) for heavy-duty EVs. According to the companies, the system can seamlessly synchronize onsite renewables, energy storage and EV batteries with local energy markets to help fleets reduce fueling costs. When deployed at scale with participating utilities, the joint architecture can provide grid services such as load balancing. Eaton will custom-engineer each Express configuration to facilitate connection to the grid and distributed energy resources (DERs). An optional skid-mounted hardware solution can expedite installation. “The new ChargePoint Express architecture, and particularly the Express Grid variant, will take DC fast charging to levels of performance and cost not previously imagined,” said Rick Wilmer, CEO of ChargePoint. “Combined with Eaton’s end-to-end grid capabilities, ChargePoint is delivering solutions to help EVs win on pure economics, regardless of tax incentives or government support.” “Accelerating electrification at scale hinges on technology that can be deployed faster while achieving new levels of reliability and efficiency at a significantly lower cost,” said Paul Ryan, VP of Energy Transition at Eaton. “Our partnership with ChargePoint is an accelerator for innovation in electrification.” The new system will make its debut at the upcoming RE+ trade show in Las Vegas. Solutions are available to order for “select customers” in North America and Europe, and deliveries are to begin in the second half of 2026. Source: ChargePoint

Tesla launches Full Self-Driving in a new region

Tesla has launched its Full Self-Driving suite in a new region, marking a significant step in the company’s progress to expand its driver assistance suite on a global scale. It is also the first time Tesla has launched FSD in a right-hand-drive market. Today, Tesla launched Full Self-Driving in Australia for purchase by car buyers for $10,100, according to Aussie automotive blog Man of Many, which tried out the suite earlier this week. Previously, Basic and Enhanced Autopilot suites were available, but the FSD capability now adds Traffic Light and Stop Sign Control, along with all the features of the previous two Autopilot suites. Tesla has officially launched Full Self-Driving in Australia for the price of $10,100 outright. The move marks a significant step in Tesla’s progress to expand the suite on a global scale pic.twitter.com/zzHa8Ngqls — TESLARATI (@Teslarati) August 28, 2025 It is the first time Tesla has launched the suite by name in a region outside of North America. In China, Tesla has “City Autopilot,” as it was not permitted to use the Full Self-Driving label for regulatory reasons. However, Tesla still lists Full Self-Driving (Supervised) as available in the U.S., Canada, China, Mexico, and Puerto Rico. The company teased the launch of the suite in Australia earlier this week, and it appeared to have been released to select media members in the region earlier this week: Tesla FSD upcoming Australia release seemingly teased bv media The rollout of Full Self-Driving in the Australian market will occur in stages, as Model 3 and Model Y vehicles with Hardware 4 will receive the first batch of FSD rollouts in the region. TechAU also reported that “the initial deployment of FSDs in Australia will roll out to a select number of people outside the company, these people are being invited into Tesla’s Early Access Program.” Additionally, the company reportedly said it is “very close” to unlocking FSD in customer cars: BREAKING: Tesla has officially announced that FSD (Supervised) is launching in Australia, marking a huge milestone for the company. The rollout will happen in stages. HW4 Model 3s and Model Ys will get it first. Tesla says it is “very close” to being unlocked in customer cars.… pic.twitter.com/r1dYnFRa6o — Sawyer Merritt (@SawyerMerritt) August 28, 2025 Each new Tesla sold will also come with a 30-day free trial of the suite. Australia is the sixth country to officially have Full Self-Driving available to them, following the United States, Canada, China, Mexico, and Puerto Rico. Here’s the first look at the suite operating in Australia: The post Tesla launches Full Self-Driving in a new region appeared first on TESLARATI.

Tesla starts Full Self-Driving rollout to owners in Australia

Tesla has already started rolling out its Full Self-Driving suite to owners in Australia after officially launching the driver assistance suite in the country yesterday. Earlier this week, Tesla seemed to be moving toward the launch of Full Self-Driving (Supervised) in Australia after numerous media members received early access to test its performance. Tesla officially launched Full Self-Driving (Supervised) in Australia yesterday. The company told media members who got early access to the suite that the rollout would begin with Hardware 4-equipped Model 3 and Model Y vehicles. Tesla launches Full Self-Driving in a new region The release would be slow and gradual, with the process performed in stages. The first stage of the rollout has already begun in Australia: The first wave of Tesla Full Self-Driving is rolling out to owners in Australia It’s here pic.twitter.com/qsQUcG6lRx — TESLARATI (@Teslarati) August 29, 2025 Tesla is reminding drivers in Australia who are using the suite for the first time that they must not become complacent while FSD is in operation. It is not fully autonomous and still requires the driver to remain attentive to road conditions and the vehicle’s surroundings. Currently, the suite is only available to purchase outright, and it comes at a cost of $10,100. A subscription model is in the works, similar to the one in the United States, but Tesla has not yet announced its plans or pricing model for this. Australia is the sixth country to receive Full Self-Driving (Supervised), or at least some version of it, as the United States, Canada, Mexico, China, and Puerto Rico all have access to the suite currently. In China, it is slightly different and is referred to as “City Autopilot” due to regulatory boundaries. Early reviews of the suite have been very strong, as local media have also had the opportunity to try it, with one journalist saying, To have this car drive me around Brisbane for an hour, we’re talking in the city, motorway, spaghetti bowl of on-ramps, it handled it so well. It was mind-blowing.” Mainstream media’s review of @Tesla‘s FSD (Supervised) after using it public roads in Australia: “To have this car drive me around Brisbane for an hour, we’re talking in the city, motorway, spaghetti bowl of on-ramps, it handled it so well. It was mind-blowing.” pic.twitter.com/Rjsh6yXk93 — Sawyer Merritt (@SawyerMerritt) August 29, 2025 The post Tesla starts Full Self-Driving rollout to owners in Australia appeared first on TESLARATI.

ASEAN Battery Conference Proposes Unified Regional Battery Ecosystem

Support CleanTechnica's work through a Substack subscription or on Stripe. Last Updated on: 29th August 2025, 11:08 am The 3rd ASEAN Battery Technology Conference (ABTC) recently wrapped up at the SAii Laguna Phuket in Thailand, marking a significant step toward a unified regional battery ecosystem and accelerating collaboration in clean energy. Attracting a broad international audience, the event drew over 340 participants from more than 20 countries across Asia, Europe, Oceania, and North America. Co-hosted by the Thailand Energy Storage Technology Association (TESTA) and five other leading battery and EV organizations, the conference served as a critical platform for major strategic announcements and partnerships that underscore the region’s collective ambition. A major highlight was the official launch of the ASEAN Battery Safety Network (ABSN), a new initiative to standardize safety practices across the region. Dr. Sing Yang Chiam, Technical Director of the Singapore Battery Consortium, and lead for the new network, spoke on its importance. “We are grateful for the strong support from ASEAN leaders in establishing the ASEAN Battery Safety Network, a critical first step in our collective journey to address battery safety challenges across the region,” Sing said. “ABSN was established to drive cross-border collaboration, knowledge exchange, and the advancement of battery safety science, laying the foundation for safer deployment and use of battery technologies while reinforcing ASEAN’s position in the global battery value chain.” The ABSN also announced a strategic partnership with UL Standards & Engagement (ULSE) to support its mission and enable faster, safer deployment of battery technologies. The conference was energized by a series of significant Memorandum of Understanding (MoU) signings that cemented cross-border collaboration and innovation. For instance, Amphenol and the Thailand Standard Swappable Battery Consortium signed a deal to standardize swappable battery packs. To advance grid-scale energy solutions, Singamas Container Holdings and Zhejiang Narada Power Source teamed up to develop and deploy Battery Energy Storage Systems (BESS) in the ASEAN region. A new strategic alliance formed between NextGEN Energy, Sineng Electric, Green Tenaga, and Half Bridge Automation will work to enhance Euro-Grid infrastructure with intelligent energy storage solutions. Additionally, Hytzer Energy and INV Corporation established a framework to accelerate the development and commercialization of solid-state battery technology. Finally, a partnership was solidified between Indonesia’s National Battery Research Institute (NBRI) and Malaysia’s NanoMalaysia Berhad (NMB) to advance technology transfer, research, and standardization within the regional battery ecosystem. Dr. Pimpa Limthongkul, Co-founder and President of TESTA. (Photo for CleanTechnica by RGBT) In a statement about the conference, Dr. Pimpa Limthongkul, Co-founder and President of TESTA, said, “ABTC 2025 marks a defining moment for ASEAN as we accelerate regional collaboration to drive innovation, safety, and sustainability in next-generation battery technologies. It reflects Thailand’s intention in building a resilient energy storage economy and ASEAN’s collective ambition to power clean mobility and robust energy systems.” The conference also announced a new collaborative whitepaper, “Navigating the Battery-Related Landscape in Southeast Asia and Beyond.” Co-authored by six ASEAN and two other organizations, the paper offers a detailed analysis of the region’s battery, EV, and BESS sectors, covering everything from the value chain to regulatory policies and end-of-life battery management. Samawit Supanpai, Deputy Governor of Phuket opens the 3rd ABTC. (Photo from ABTC) Officially opened by Samawit Supanpai, Deputy Governor of Phuket, the event concluded with insightful panel discussions and a plenary speech by Nobel Laureate Prof. M. Stanley Whittingham on the future of lithium batteries and the challenges of localized manufacturing. “Thailand and Asia are building on regional strength, turning crisis into opportunities. We are accelerating the development of EVs because we no longer just assemble them—we’re now building batteries from the cell level up. This fills a key missing link in our supply chain and positions Asia as a leader in clean energy,” Pongpol Yodmuangcharoen, Secretary to the Minister of Industry, said as he highlighted a pivotal strategic shift for Thailand and the wider region. He also emphasized three core principles for future-ready industries: Transparency, Innovation, and Circularity, which are designed to transform trade pressures into bargaining power and waste into value. “We are confident that ABTC 2026 in Penang, Malaysia, will build on this momentum by bringing together industry leaders across the comprehensive battery and EV value chain. The event will span the entire supply and value chain of these industries,” Dr. Rezal Khairi Bin Ahmad, CEO at NanoMalaysia Berhad said reflected on the progress of the biennial event. Sign up for CleanTechnica's Weekly Substack for Zach and Scott's in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News! Advertisement Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here. Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent. CleanTechnica uses affiliate links. See our policy here. CleanTechnica's Comment Policy

CIS Tenders 5 & 6 open in Western Australia eyeing 2.4GWh BESS

CIS Tenders 5 & 6 open in Western Australia eyeing 2.4GWh BESS - Energy-Storage.News Skip to content

Battery Power Online | How to Select Batteries Based on Technology, Lifespan, Capacity, and Maintenance to Determine Total Cost of Ownership

Contributed Commentary by David Steele, Trojan Battery Company July 10, 2025 | The onetime purchase price for a flooded lead-acid battery can be as little as half that of advanced technologies. However, many consumers do not account for Total Cost of Ownership (TCO). Lifetime costs of flooded batteries—including watering, maintenance, multiple replacement batteries, and employee time—can equal or exceed other advanced battery types. This article provides some insights and formulas for comparing the overall estimated lifetime costs of flooded lead-acid, VRLA, and lithium (LiFePO4) batteries. What Goes into Calculating Battery TCO? Understanding the application and which batteries are best suited for the vehicle or other equipment is crucial to accurately costing out a battery system. Like anything else, products are made for specific use. If misapplied, failures and issues can occur. The least expensive option is not always the best option. Creating a TCO calculator allows decision makers to compare battery models, battery technology, Ampere-hour (Ah) capacity, numbers of batteries for each type, along with average costs that make up a system. The tool can be used to recommend solutions that best meet the specific application needs. Identifying the Specifications for Each Battery Type Criteria need to be established to quantify TCO for the three main battery types—flooded lead-acid, AGM, and lithium—we need to compare apples to apples as much as possible. Each battery type has an average battery life, a one-time cost per battery, and power output capability. One type also requires maintenance time. To determine the number of batteries for an application, it’s important to understand that it can vary by chemistry. Due to energy density, available power, and quicker charge acceptance, lithium (LiFePO4) is not a one-to-one conversion ratio from lead-acid. In some (but not all) motive applications, about half the number of LiFePO4 to flooded lead-acid batteries may be needed. This ratio is subject to change based on various conditions, such as vehicle type, amp draw, and whether it’s been modified. In the example below, the scenario is three lithium batteries for eight flooded lead-acid. Battery Type Flooded Lead-Acid AGM Lithium-Ion Initial purchase cost $ $$ $$$ Number of batteries (Example only) 8 8 3 Note: Each $ indicates a higher initial purchase cost for each battery type. Table is based on batteries for equipment in which (4) 6V lead-acid batteries are the baseline with (2) 24V lithium units as the alternative. Factoring in Replacement Costs Other factors include the number of sets needed to replace the originals in a given time period. Battery Type Flooded Lead-Acid AGM Lithium-Ion Initial purchase cost $ $$ $$$ Number of batteries (Example only) 8 8 3 Lifespan 3-4 years 4-5 years 10 years Replacements 10Y 3 2 0 Note: Each $ indicates a higher initial purchase cost for each battery type. In this scenario, three additional full replacement sets of flooded lead-acid and two full replacement sets of VRLA are needed over a 10-year span. That’s four full sets of flooded lead-acid and three full sets of VRLA batteries purchased in that ten-year period. During the decade, there are zero replacement sets for lithium. This helps determine the real total cost of the systems, including replacement costs, over a ten-year period. Investment of Maintenance Time and Effort Another part of the equation that must be considered is the maintenance time and equipment to maintain flooded batteries. Battery Type Flooded Lead-Acid AGM Lithium-Ion Initial purchase cost $ $$ $$$ Number of batteries 8 8 3 Lifespan 3-4 years 4-5 years 10 years Replacements 10Y 3 2 0 Maintenance time 10Y 86 hours 0 0 Note: Each $ indicates an increase in cost. In this example, the individual flooded lead-acid units will require regular watering intervals. This is shown as 10 minutes per week over 52 weeks. It is based on manual watering—no special equipment such as single point watering systems. Over ten years, those weekly watering requirements can amount to 86 or more hours, not counting the costs of water. TCO: What are the True Battery Costs —for One Vehicle or a Fleet? Many factors go into a decision about motive battery power. Examples include terrain, storage, expected usage, and environmental conditions. However, over a ten-year period, it is clear that lithium is the winner, coming in with a total return in 1.5 to 1.8 years. AGM/VRLA comes in at almost double that of LiFePO4 with a four-year return on investment. Battery Type Flooded Lead-Acid AGM Lithium-Ion Initial purchase cost $ $$ $$$ Total Cost of Ownership per year 10Y $$$ $$ $ Return on Investment over Flooded Lead Acid Years 0 3.97 1.83 Note: Each $ indicates an increase in cost. Calculating Your TCO for Greatest Impact on Operations In summary, all battery technologies depicted in this TCO calculation are sufficient to run various types of equipment. The most important part of the equation is how they are being applied and what is expected of them. There is no “one-size-fits all” solution for batteries. That is why there are many battery technologies and chemistries in the marketplace. Applications and associated needs must be identified upfront and discussed with experienced power solutions specialists. They can determine the best technology for an application. Author Note: The figures used in this article are for informational purposes only and are based on assumptions which may not be representative of an individual user’s experience. No guarantee or representation is being made concerning an individual user’s total cost of ownership. David Steele has been with Trojan Battery Company for 2.5 years. He currently serves as Director of Sales – OEM, Lithium. Prior to joining Trojan Battery Company, he spent 26 years in the industrial battery/material handling industry, holding positions in OEM and regional management. He can be reached at david.steele@cdtrojan.com

Tesla is overhauling its Full Self-Driving subscription

Tesla (NASDAQ: TSLA) recently talked about a variety of topics with Wall Street firm Piper Sandler, as the firm released a new note on Friday about their meeting with the company’s Investor Relations team. According to the note from Piper Sandler, Tesla talked in detail about the Semi program, Optimus, and its potential valuation given its capabilities, the rollout of Robotaxi in Austin, and Full Self-Driving progress in the United States. Tesla Semi Ramp The Tesla Semi is set to enter mass production in 2026 at a dedicated factory near the company’s Gigafactory in Reno, Nevada. The Semi has already been in pilot program testing, as Tesla has partnered with a few companies, like Frito-Lay and PepsiCo., to perform regional logistics. It has been met with excellent reviews from drivers, and it has helped give Tesla a good idea of what to expect when it makes its way to more companies in the coming years. Piper Sandler said that it is evident Tesla is preparing for a “major ramp,” but it is keeping its expectations low: “We’ve never expected much from this product, but we’d love to be proven wrong (Tesla is clearly prepping for a major ramp).” Tesla Optimus and its value internally and externally Optimus has been working in Tesla factories for some time, but its expectations as a product offering outside of the company internally have major implications. Its role within Tesla factories, for now, is relatively low, but Optimus is still doing things to assist. By this time next year, Piper Sandler said Optimus should have bigger responsibilities: “By this time in 2026, Optimus should be moving/staging parts within Tesla’s facilities.” Outside of Tesla, Optimus could be a major beneficiary for companies as it could be a more affordable way to handle tedious tasks and manual labor. The firm believes that if Optimus can work 18-hour shifts, a cost of $100,000 per unit “would be justified.” Tesla Robotaxi Expansion The big focus of the firm with Robotaxi was Tesla’s expansion of the geofence in Austin this week. It was substantial, bringing the Robotaxi’s total service area to around 170 square miles, up from the roughly 90 square miles that rival Waymo is offering in the city. Tesla Robotaxi geofence expansion enters Plaid Mode and includes a surprise Tesla has doubled its geofence three times since its launch in late June, and it also revealed that its fleet of vehicles has expanded by 50 percent. It did not give a solid number of how many vehicles are operating in the fleet. Tesla Full Self-Driving v14 launch Tesla’s Full Self-Driving suite is set to have a fresh version, v14, rolled out in either September or October, and there are some pretty high expectations for it. CEO Elon Musk said: “The FSD release in about 6 weeks will be a dramatic gain with a 10X higher parameter count and many other improvements. It’s going through training & testing now. Once we confirm real-world safety of FSD 14, which we think will be amazing, the car will nag you much less.” There is also some expectation that v14 could be the public release of what Tesla is running in Austin for Robotaxi. The firm confirmed this in their note by stating it “should enable Tesla owners to use software that is on par with Robotaxis in Austin.” The only real hold up would be regulator skepticism, but Tesla can alleviate this with strong data. The firm maintained its ‘Overweight’ rating and the $400 price target it holds on the stock.

10 Common Myths About Electric Cars & Clean Energy — And How To Respond

Support CleanTechnica's work through a Substack subscription or on Stripe. We’ve been covering clean technologies here on CleanTechnica for almost 18 years. I’ve been doing so for 16 years. It’s been a fun topic to cover as solar energy, wind energy, and electric vehicles have grown tremendously and costs have fallen off a cliff. However, in all of that time, I’ve had to deal with myths about cleantech that are harmful and persistent. Many of the major myths from back then continue to this day, and others have been thrown onto the pile and become popular. Unfortunately, it’s just very hard to get rid of these. One thing I learned many years ago from Skeptical Science and their efforts to counter climate myths is that people don’t respond to long, complicated debunkings. In fact, those are more likely to backfire and reinforce myths in people’s heads! It may sound crazy, but this is the human mind we’re dealing with. It’s much more effective to give a simple and clear response that provides an easy concept for people to latch onto to replace the simple myth they had heard and thought might (or must) be true. So, below are 10 common myths about EVs and clean energy, and ways you can counter them. Feel free to offer your own better ideas if you have them, but, to be honest, all of these responses have surely been crowdsourced from readers over the years. For those who prefer longer, more detailed answers, we’ll go ahead and provide those for you on some of these points as well. Stay tuned. Electric Vehicles Myth: You have to spend a lot of time charging an EV. Truth: It typically takes less than a minute to charge an EV each week. Electric cars now come with hundreds of miles of range. Most people drive 40 miles or less each day. If they can plug in at home or work every 2–3 days, that should be plenty. It takes just a few seconds to plug in or unplug, so that adds up to a minute or so (probably less) that someone has to spend charging their EV each week. If you’re thinking about road trips, it’s true that it takes a bit longer for an electric car to charge than it takes a gas car to fill up, but the vast majority of driving and fueling/charging is from daily transportation needs, not occasional road trips. Also, you don’t have to stand next to the car while it charges — you can go get coffee, get food, use the restroom, watch something on YouTube, work, scroll social media, rest your eyes, walk the dog, or do other things while your car charges. Again, it just takes a few seconds to actually plug in and unplug. Okay, I started with a longer one, but let’s move on. Myth: EV batteries need to be replaced after a few years. Truth: EV batteries almost always come with an 8-year warranty, and that warranty guarantees that the battery has 70% or more of its original energy storage capacity. Automakers don’t provide warranties they expect will result in a financial loss. These EV batteries are more likely to last 15 years than have to be replaced after a few years. In fact, most EV batteries probably will last 15 years or so. I think the issue here is that people think about 12V batteries that are in all cars, which often only last 2–3 years (at least in a place like Florida). Those are completely different batteries and incomparable. Myth: Electric cars are actually really dirty and polluting. Electric cars are much cleaner than gasoline-powered cars, even conventional hybrids, all across the grid. With more and more electricity coming from renewable energy (which accounts for most new power capacity in the United States year after year this decade), they just get cleaner and cleaner, too. The little bit of extra emissions created from producing batteries for electric cars is quickly negated by the lower pollution from electric car operation (zero emissions) and charging. Myth: There aren’t affordable electric car options. Not that long ago, it was very hard to find affordable electric cars. Now, however, there are several electric car models that have a lower MSRP than the average new car sold in the United States. Additionally, there’s now a vast used electric car market. You can get great deals on used electric vehicles of all different models and vehicle classes. Myth: An EV could very likely burn down your house. While there have been a few fires caused by EVs charging, this is an extremely uncommon. Gasoline is also flammable, by the way, and there have been many cases of gas tanks and gas cars catching fire and burning down houses as well. Things can happen, and when you’ve got energy densely packed — whether into batteries or gasoline — it can catch fire. However, battery packs are heavily protected and managed to avoid this, and there are millions of vehicles sold every month that will never catch fire. Renewable Energy Myth: Wind and solar energy are expensive. Wind and solar power are actually the cheapest options for new power capacity now, which is why they have accounted for most new power capacity in the past several years. Myth: Wind and solar energy take up a lot of land. Wind turbines and solar power systems don’t actually need a lot of land, and they can be easily co-located with farmland (wind and solar) or rooftops (solar). In fact, wind power and solar power systems help farmers around the world, as they provide supplemental income and can also help with crop growth. Myth: We can’t add much more solar and wind energy to the grid because they’re intermittent energy sources. The sun doesn’t shine all the time and the wind doesn’t blow all the time, but with modern technology (we live in the age of AI after all), it’s not difficult for utilities

Hitachi Energy acquires Powin stake in Eks Energy

Hitachi Energy acquires Powin stake in Eks Energy - Energy-Storage.News Skip to content

Battery Power Online | EV Battery Innovation Will Push Manufacturers to New Heights

Contributed Commentary by Eric Symon, Panasonic Connect North America July 29, 2025 | We’re past the midway point of the calendar year, and a mixed outlook remains for the future of electric vehicles in the United States and globally. Q2 revealed growth for some manufacturers, declines for others, and a cautious outlook for the rest of the year stateside amid announcements that would roll back discounts for consumers. This, of course, directly impacts EV battery manufacturing. As expected, there have been plant closures and other delays in 2025, while other manufacturers are continuing to push forward with production and future innovation (for example, LFP batteries). While it is true that battery production needs will be determined by vehicle interest, there are two sides to this coin. An electric vehicle and hybrid future will only go as far as battery innovation takes it. Smaller cells, longer lasting units, and more mileage are the desired outcomes that will drive even greater adoption to make EVs a more reliable, practical, and long-lasting vehicle option. To achieve this, the industry will need innovation in battery composition, chemical mix, and recycling and reuse to make electric vehicles a more attractive proposition. This will push manufacturing to new heights as manufacturers digitize and modernize to keep pace. Leverage MES/DMP Systems for Greater Operational Efficiency We’ve seen a mixture of manufacturing execution systems (MES) and digital manufacturing platforms (DMP) have success in the broader manufacturing world. The ability to optimize end-to-end manufacturing is a core requirement to stay competitive and profitable in today’s chaotic supply chain. As such, it’s a no-brainer that EV battery manufacturers (and EV automative manufacturers) will find success leveraging these solutions if they haven’t already. For new plants to be built, it goes without saying that an MES or DMP solution will be part of the rollout to connect disparate systems, material inputs, and machines from the first to last step of the manufacturing process. However, there are caveats to consider when ensuring success in this highly complex line of EV battery production that manufacturing decision makers need to account for. Processes like chemical mixing can stress manufacturing lines. These mixes are in flux and are beholden to the materials and inputs that are incredibly specific for batteries. Not to mention, continued innovation means that batteries built today will not be the batteries built tomorrow. Therefore, any MES or DMP deployment should be done through a critical lens. For example, is the solution able to model batch, discrete, and hybrid types of complex processes in one factory? This is important to remain agile and avoid waste. Can it manage traceability down to the individual cell level? This is critical to managing all raw inputs that comprise an EV battery’s “chemical slurry” and proactively address issues early on in the production process. These are the kinds of questions to ask when making important management decisions. Do More with Data As precision machinery, automation, and robotics proliferate on the EV battery manufacturing floor, more data is being produced than ever before. Connected machines that leverage sensors, for example, consistently generate data. The race is on for businesses to better capture that data, accurately and with speed, and feed it back into improving the manufacturing process. This is critical to allow manufacturers to take advantage of new aggregation and analytics tools that are being modeled and built every day. This includes digital twins for scenario planning, edge computing for faster reporting and decision making, and artificial intelligence (running trained algorithms) for a proactive approach to repairs, diagnostics, and performance. With an ongoing talent shortage and resulting labor gap, getting these tools up and running takes on even greater importance. EV battery manufacturing is a relatively new space in the United States, and it requires not only the right machinery, materials, and software, but also the right engineers, chemists, and technologists. Other nations are more experienced in the space, so it’s important that manufacturers find stability by building processes and systems for how things should work. Then, recruiting and retaining talent—and plugging in talent that may come from other industries—becomes a more realistic proposition. Remain Agile in the Face of Change Stating the obvious, this industry, while incrementally moving forward, continues to face challenges en route to its destination. It is still believed that electric vehicles will play a part in this country’s automotive future, but how and what that looks like remains in a constant state of flux and under intense discussion. Capitalizing on today while being prepared to tackle tomorrow requires agility. It’s okay to start small and scale when deploying new systems and processes, such as MES or DMP, for example. In fact, in many situations, it can be advised. EV battery manufacturing is highly complex and intricate, and evolving every day. Deploying small proofs of concept or trials when revamping systems and processes is one of the most effective ways to realize time to value and scale with confidence across the entire production line. From there, businesses can find and understand where there are opportunities and advantages gained from managing a complex production line through the right software. While we don’t have a crystal ball, innovation in battery design will be a catalyst for EV growth in the United States. With that innovation comes a need to produce—and to do so with speed, accuracy, and efficiency to remain competitive in a challenging environment. MES/DMP systems, doing more with data, and remaining agile are the tip of the iceberg, as well as areas where manufacturing leadership can drive change. Eric Symon is head of smart manufacturing at Panasonic Connect North America. Eric has held executive positions at market-leading software and professional services companies delivering value through digital transformation to customers in manufacturing, aerospace and defense, and retail industries. Eric holds a B.S. from the Pennsylvania State University. He can be reached at Eric.Symon@us.panasonic.com.

Tesla expands crazy new lease deal for insane savings on used inventory

Tesla has expanded its new lease deal, offering people insane savings on used inventory. Last week, we reported on Tesla offering crazy good lease deals on some of its used inventory, as people were able to grab monthly payments for as little as $225 per month with no money down. There was only one catch: the deal was only available in California and Texas. Tesla offers new deal on used inventory that you won’t want to pass up However, Tesla has been working hard to get the lease deal expanded, and it finally has. Last night, Tesla’s VP of Finance, Sendil Palani, confirmed the deal had made it to three additional states. Palani explained that the deal was only available in California and Texas because the leasing process requires working through regulatory hurdles in each state. He said it “involves a nontrivial amount of work,” which makes things more difficult to iron out. Tesla was able to work through the hurdles in three states, expanding the deal to New York, New Jersey, and Florida. It is currently active in those states, Palani said: Tesla’s used lease deal has expanded to three new states: New York, New Jersey, and Florida Expanding to new states requires “a nontrivial amount of work,” but more states could receive the deal soon! — TESLARATI (@Teslarati) August 29, 2025 Tesla is really making a concerted effort to push its inventory out the door, and many areas already are running low on both new and pre-owned inventory. It has cut prices on some new inventory, while offering these new lease deals on used vehicles that remain. It is beneficial to the consumer for obvious reasons: cheaper payments and the ability to get a great deal on a car for no money down. Tesla is also getting rid of vehicles that were once thought to be intended for the Robotaxi fleet, but it appears these older hardware vehicles are no longer in the company’s plans for that purpose. This is the first time Tesla has offered lease deals on used inventory, as it has only offered an outright purchase option in the past. In an effort to boost deliveries and rid itself of older cars, these lease deals are truly beneficial for both parties. It is only a wonder how long they will last. The post Tesla expands crazy new lease deal for insane savings on used inventory appeared first on TESLARATI.

ESS Appoints Industry Veteran Jigish Trivedi as Chief Operating Officer to Drive Next Phase of Growth

Support CleanTechnica's work through a Substack subscription or on Stripe. Wilsonville, Oregon — ESS Tech, Inc. (“ESS” or the “Company”) (NYSE:GWH), a leading manufacturer of iron flow long-duration energy storage (LDES) systems for commercial- and utility-scale applications, today announced a significant addition to the executive leadership team with the appointment of Jigish Trivedi as Chief Operating Officer. Jigish brings over 30 years of executive experience in scaling global operations for high-growth technology companies. “We are thrilled to welcome Jigish to the ESS executive team,” said Kelly Goodman, Interim Chief Executive Officer. “His extensive experience in the energy and semiconductor sectors, combined with a proven ability to build world-class, scalable operations, is precisely what ESS needs as we execute on our strategic pivot to the Energy Base. Jigish’s leadership will be invaluable in driving operational excellence across the organization.” Mr. Trivedi joins ESS from Electric Hydrogen, where as Senior Vice President of Operations and Global Supply Chain, he helped scale the company from 10 to over 350 employees and was instrumental to its rise to “unicorn” status. His career also includes senior leadership roles at First Solar and Micron Technology, where he led initiatives across operations, product development, and global supply chain management. “I am excited to join ESS at such a pivotal moment in its journey,” said Jigish. “The company’s mission to enable the clean energy transition with innovative long-duration storage solutions is incredibly compelling. I look forward to working with the entire team to build a robust operational foundation and product that will support our rapid growth and deliver for our customers worldwide.” About ESS, Inc. At ESS (NYSE: GWH), we deliver safe, sustainable, long-duration energy storage to ensure energy abundance and security. As energy demand continues to grow, our solutions provide essential reliability and resilience to people, communities, and businesses in the United States and throughout the world. Our technology uses earth-abundant iron, salt and water to deliver environmentally safe solutions capable of providing 10+ hours of flexible energy capacity for commercial and utility-scale energy storage applications. Established in 2011, ESS enables project developers, independent power producers, utilities and other large energy users to deploy reliable, sustainable long-duration energy storage solutions. For more information visit www.essinc.com. This release contains certain forward-looking statements, including statements regarding the Company and its management team’s expectations, hopes, beliefs, intentions or strategies regarding the future. The words “anticipate”, “believe”, “continue”, “could”, “estimate”, “expect”, “intends”, “may”, “might”, “plan”, “possible”, “potential”, “predict”, “project”, “should”, “will” and “would” and similar expressions may identify forward-looking statements, but the absence of these words does not mean that a statement is not forward-looking. Examples of forward-looking statements include, among others, statements regarding the Company’s productization, manufacturing and delivery of the Energy Base and operational scaling. These forward-looking statements are based on the Company’s current expectations and beliefs concerning future developments and their potential effects on the Company and involve a number of risks, uncertainties (some of which are beyond the Company’s control) or other assumptions that may cause actual results or performance to be materially different from those expressed or implied by these forward-looking statements, which include, but are not limited to, delays, disruptions, or quality control problems in the Company’s manufacturing operations; issues related to the development and launch of the Energy Base product; failure to raise additional capital on acceptable terms or at all; and other risks and uncertainties described more fully in the section titled “Risk Factors” in the Company’s Quarterly Report on Form 10-Q filed on May 15, 2025, and the Company’s other filings with the U.S. Securities and Exchange Commission. Except as required by law, the Company is not undertaking any obligation to update or revise any forward-looking statements whether as a result of new information, future events or otherwise. Sign up for CleanTechnica's Weekly Substack for Zach and Scott's in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News! Advertisement Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here. Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent. CleanTechnica uses affiliate links. See our policy here. CleanTechnica's Comment Policy