RS offers Omron system to simplify control panel design

RS offers Omron Automation’s Value Design for Panel system — a comprehensive portfolio of industrial control panel products designed to help panel builders, machine builders and end-users reduce their total cost of ownership. Control panels are essential to industrial operations — a virtually inescapable cost of doing business — and have been for some time, generating steady global market demand. Now, the increased adoption of Industry 4.0 trends and technologies — including automation, machine learning, the IIoT, AI, robotics, edge and cloud computing, digital twins, and virtual and augmented reality (VR and AR) — has market demand surging. The global industrial control panel market is currently valued at $15 billion and is projected to grow to a value of $25 billion by 2033. The complexity and cost involved in designing industrial control panels can vary widely. Some industry experts estimate that panel design and engineering costs often account for approximately 45% of total control panel cost, or roughly the same as all the components and devices they contain, while others claim that it can account for up to a whopping 80% of the total cost. As such, solutions engineered to ease design complexity, optimize performance, minimize labor, and facilitate future growth — like Omron Automation’s Value Design for Panel system — can have an outsize impact on total cost of ownership. Omron Automation’s Value Design for Panel system offers a wide variety of essential control and switching components engineered to speed up panel design and engineering, simplify integration, improve efficiency, reliability, and durability, support scalability and sustainability, and reduce downtime, including limit switches, relays, pushbuttons, timers, and counters. These components feature: Slim form factors with standardized heights that reduce dead space and support side-by-side mounting at 55°C ambient temperatures and, in turn, enable simplified, high-density layouts that conserve available space, maximize functionality, improve thermal management and product lifetimes, and facilitate scalability. Unified top and bottom I/O terminals with Push-in Plus technology and Front-in/Front-release Wiring that enable the quick, easy, and reliable termination of stranded wires, single wires, and ferrules, reducing wiring work by ~60% compared to hard-wired screw terminal solutions while also improving safety, workability, and vibration resistance and eliminating the threat of accidental disconnection. eCAD libraries and CE, UL, and CSA certifications that simplify the design and build process — reducing electrical design drawing and data creation work by up to 50% while minimizing errors — and significantly accelerate global deployment, shortening lead times. Green design elements that conserve energy and resources, reduce greenhouse gas emissions, and support organizations’ efforts to achieve carbon neutrality. and include: Control components essential for end-to-end automation solutions, such as DIN rail power supplies, temperature controllers, timers, counters, digital panel meters, programmable relays, and energy monitoring devices. Switching components designed to make manufacturing flexibility more attainable than ever, such as limit switches, basic switches, pushbutton switches and indicators, wireless pushbutton switches, electromechanical relays, solid-state relays, terminal blocks, magnetic contactors, and monitoring products, including monitoring relays, thermal image controllers, liquid leakage sensors, and motor condition, undervoltage and phase, and insulation resistance monitoring devices. All of the control and switching components in Omron Automation’s Value Design for Panel system are backed by more than 90 years of R&D experience and installed performance, and — according to an OMRON investigation in March 2023 — several of these components reduce greenhouse gas emissions by over 50% compared with previous models (from 2016 and earlier) through a combination of power savings, resource savings, and reduced waste, including: Single-phase switch mode power supplies (SMPS), like the S8VK-G, which enables quick and easy installation, delivers high power density (15–480W) in a compact package that’s 13% smaller than comparable SMPS, ensures stable, reliable operation in harsh industrial environments exposed to high vibration and operating temperatures extending from -40°C to +70°C, and has a high mean time before failure (MTBF) for long-lifetime performance. Three-phase SMPS, including S8VK-WA models, which are engineered to maintain three-phase balance regardless of operating conditions — negating the need for load management, utilizes the world’s smallest class of compact body — requiring less than half the space of other Omron Automation SMPS and weighing approximately 35% less, and feature integrated maintenance and power supply indicators to help maximize uptime. The XW2K ultra-compact interface wiring system, which enables more compact control panels with greater functionality, is smaller than any other competing solution currently available on the market, and supports both horizontal and vertical mounting to maximize space efficiency. S8V-CP electronic DC circuit protectors, which reliably protect against short circuits and overcurrent, facilitate the sequential start-up of branch circuits to avoid errors, and feature four or eight branches in a single device — enabling significant space savings compared to four or eight conventional circuit breakers — and an alarm signal output to alert upstream controllers of abnormal operation. Digital temperature controllers with unique low-power-consumption displays. Motor protective relays and timers. RS offers an extensive portfolio of Omron Automation products, including a comprehensive collection of panel building products. For more information about these Value Design for Panel products, check out the RS Expert Advice video podcast with Juan Carlos Garcia, Product Manager – Components at Omron Automation, the company’s Industrial Control Panel Component Selection Guide and panel building page, and the links embedded above. For more expert insights from Omron Automation, check out the company’s other contributions to the RS Expert Advice series. For more information, visit us.rs-online.com. The post RS offers Omron system to simplify control panel design appeared first on Engineering.com.

Anker SOLIX early Black Friday Sale takes up to 65% off expanded power station lineup from $158, Lectric, EcoFlow, Husqvarna, more

We’re kicking off this week’s Green Deals with Anker’s full SOLIX early Black Friday Sale that is taking up to 65% off a large lineup of power stations and solar bundles starting from $158. One of the notable standouts is the SOLIX F3800 Plus Portable Power Station with a FREE protective cover at a new $2,499 low. From there, we have the best bundles on both Lectric’s standard XP4 and long-range XP4 750 e-bikes with up to $514 in FREE gear starting from $999, as well as the latest 48-hour flash sale from EcoFlow, a rare discount to the annual low for Husqvarna’s Power Axe 350i, and more waiting for you below. And don’t forget about the hangover deals from last week that are collected together at the bottom of the page, rounded up in our latest edition of Electrified Weekly here. Head below for other New Green Deals we’ve found today and, of course, Electrek’s best EV buying and leasing deals. Also, check out the new Electrek Tesla Shop for the best deals on Tesla accessories. more…

Schaeffler to supply dual inverters powered by onsemi’s SiC for PHEV pickup trucks in North America

Schaeffler announced that it will supply a dual inverter, featuring silicon carbide (SiC) technology from its onsemi, for use in a plug-in hybrid (PHEV) pickup truck platform in the North American market. The contract covers nearly one million units over its lifetime, with series production scheduled to begin by the end of 2027. The dual inverter controls two key functions. First, it manages the electric drive for vehicle auxiliary units by integrating a starter-generator into the belt drive of the internal combustion engine, employing conventional silicon insulated gate bipolar transistors (IGBTs) for this smaller electric motor. Second, it serves as a traction inverter for the primary electric drive motor, delivering over 200 kW of output through the use of onsemi’s EliteSiC SiC MOSFETs. According to Schaeffler, the use of SiC technology in the traction inverter enables very high switching speeds and minimal electrical losses, which supports an extended all-electric driving range for PHEVs. The inverter was specifically designed to meet the requirements of OEMs for installation space, performance and overall inverter efficiency. “This order recognizes the capabilities of our inverter experts in Deer Park, who were able to realize this highly specialized dual inverter with demanding requirements in a short period of time,” said Thomas Stierle, CEO E-Mobility at Schaeffler. “We are proud to deliver this product for use in plug-in hybrid pickup trucks.” “We are committed to driving the next generation of electrified mobility through our advanced EliteSiC technology,” said Hassane El-Khoury, CEO of onsemi. “By integrating our silicon carbide expertise into Schaeffler’s dual inverter platform, we are enabling a new standard for plug-in hybrid pickup trucks with extended electric driving range and enhanced vehicle performance.” Source: Schaeffler

Tesla China rolls out Model Y L V2L adapter, and it’s free for early owners

Tesla China has released a useful new accessory for the Model Y L, and it is free for some owners. With the accessory, the Model Y L effectively becomes a giant power bank that owners can use to power appliances when they are camping, or if their homes are hit by a power outage. Tesla Model Y L V2L adapter Tesla China announced the rollout of the Model Y L’s AC external power adapter on social media platforms such as Weibo. As per the product’s advertisement, the Model Y L could provide up to 2,200W of power with its adapter, allowing it to support numerous appliances on the go. Of course, but could also be used to charge devices during power outages. Tesla China notes that the adapter’s current is 220V, and it also features an IP44 protection grade. Tesla notes that the adapter could operate at temperatures between -30℃ ~ +50℃. The Model Y L’s V2L functionality would not work if the vehicle’s battery is less than 10%, however. Tesla China’s official shop is selling its AC external power adapter for a reasonable price. The product could be purchased for RMB599, which is equivalent to $85. That’s a great price for an accessory that could make car camping sessions several times more convenient. $TSLA NEWS : Tesla China just released a video about the external power supply (V2L) for the Model YL. pic.twitter.com/UCslCDDXiC — Tsla Chan (@Tslachan) November 10, 2025 $TSLA Tesla China Shop Starts Selling 'AC External Power Adapter'<The price seems reasonable.> : CYN 599 : 120,000원 : $85*This adapter is for Tesla Model YL vehicles only. pic.twitter.com/Dc9tge3Mwt — Tsla Chan (@Tslachan) November 10, 2025 $TSLA Additional information about external power supply adapters for Model YL*Model YL Owners can now purchase the adapter for free!– Current 10A, voltage 220V, protection grade IP44, operating and storage temperature -30℃ ~ +50℃.– The V2L functionality is unavailable… pic.twitter.com/ZQ5AQ2j7W4 — Tsla Chan (@Tslachan) November 10, 2025 Free for early Model Y L owners While the Model Y L’s AC external power adapter is priced reasonably at the Tesla China shop, the accessory is available for free for early owners of the extended wheelbase six-seat all-electric crossover. This was highlighted in a message that Tesla China reportedly sent to owners of the vehicle. “Your Tesla account is eligible for a free Model Y L dedicated AC external power adapter. Please log in to the online store to add the adapter to your cart. Once the system verifies it correctly, the price will automatically change to 0 yuan before placing the order. We will send it to you via express delivery subsequently. “This free qualification is only for the first owner of the Model YL who did not receive an AC external power adapter at pickup, valid until February 28, 2026. Failure to place an order upon expiration will be considered as a waiver of eligibility. If there is a temporary shortage of goods, please be patient and we will reschedule the replenishment by the end of January 2026,” Tesla China wrote. The post Tesla China rolls out Model Y L V2L adapter, and it’s free for early owners appeared first on TESLARATI.

Tesla prepares to expand Giga Texas with new Optimus production plant

Tesla is preparing to expand Gigafactory Texas once again with a brand new facility that will house the eventual manufacturing efforts for Optimus, its humanoid robot. It is already building some units on a Pilot line at the Fremont Factory in Northern California, but Tesla is planning to build the vast majority of its Optimus project at Gigafactory Texas. Tesla Optimus gets its latest job, and it’s not in the company’s factories It will build one million units per year in Fremont, but CEO Elon Musk said the company would build 10 million units every year in Texas at a new building at Giga Texas. Musk said: “I think there could be tens of billions of Optimus robots out there. Um, now obviously it’s very important we pay close attention to safety here. Then a 10 million unit uh per year production line here the I don’t know where we’re going to put the 100 million unit production line. on Mars. Maybe on Mars, I don’t know.” Evidently, Tesla is ready to begin thinking about the production efforts of Optimus beyond a theoretical standpoint and is starting to prepare for the construction of the manufacturing plant on Giga Texas property. Drone operator Joe Tegtmeyer recognized Tesla construction crews performing ground leveling and clearing efforts at the plant earlier today: Giga Texas News! A brand-new, stand-alone factory is starting construction! This follows the Shareholders meeting & info that a 10-million-per-year @Tesla_Optimus production facility “on the Giga Texas campus” will be built & enter into production in 2027! Here are some… pic.twitter.com/7ig5DohfOt — Joe Tegtmeyer (@JoeTegtmeyer) November 10, 2025 Production is still slated for 2027, at least at Gigafactory Texas. As previously mentioned, the company is building some units in Fremont for the time being, at least until subsequent versions of the Optimus project advance. Tesla has done a great job of advancing Optimus forward, but it also has truly grand expectations for the project. Musk said it could potentially be the biggest product in the history of the planet, as it will revolutionize the way humans perform tasks, probably eliminating monotonous tasks from everyday life. The post Tesla prepares to expand Giga Texas with new Optimus production plant appeared first on TESLARATI.

Siemens and NEC partner to advance robot motion planning

Siemens Digital Industries Software announced that it has signed a Technology Partner Program Agreement with NEC to expand collaboration in robot 3D simulation. The two companies will jointly develop a robot teaching automation solution that integrates NEC’s “Robot Task Planning” digital twin service with Siemens’ Process Simulate software from the Tecnomatix portfolio. The collaboration aims to help manufacturing customers optimize operations, improve efficiency, and support data-driven management. Delivered as part of NEC’s BluStellar initiative, the NEC Robot Task Planning software is equipped with a proprietary algorithm that optimizes the coordinated operation of multiple robots and automatically generates robot motion plans using AI. Traditionally, the motion planning for multiple robots was handled manually by engineers through a process called teaching. This approach is complex and time-intensive, as creating motion plans for each product on a manufacturing line requires considerable effort and cost. Consequently, production lines using multiple robots often experience delays before becoming operational. As part of this collaboration, NEC Robot Task Planning has been integrated into the Process Simulate user interface, allowing users to execute robot motion plan creation with a single click, significantly reducing the workload required for teaching. This capability complements the currently available automatic path planning and robot programming tools available in Process Simulate. In addition, it shortens the production line setup period, optimizes cycle time, enables fact-driven management and facilitates the sharing and transfer of operational know-how that is often dependent on individual expertise. To learn more about Siemens’ Process Simulate software, visit plm.sw.siemens.com/en-US/tecnomatix/process-simulate-software. To learn more about NEC’s BluStellar, visit nec.com/en/global/necblustellar/index.html. The post Siemens and NEC partner to advance robot motion planning appeared first on Engineering.com.

NIU unveils bold new urban and off-road (but street legal!) electric motorbikes

NIU is back at EICMA 2025 (the Milan Motorcycle Show) with a fresh lineup of electric two-wheelers that push the boundaries of performance, design, and smart connectivity. The Chinese electric mobility giant, already known for selling over 5 million electric scooters and motorcycles across over 50 countries, used the Milan show to unveil its 2026 product range – and it’s clear NIU is looking to hang on to that leader status. more…

Radian Thermal expands liquid cold plate design capabilities for high-density cooling

Radian Thermal Products, a global manufacturer of cooling devices, has expanded its line of skived micro-fin cold plates for high-power-density cooling across industries from automotive to aerospace. Liquid cold plates are precision-engineered heat exchangers that transfer heat away from critical components through internal channels carrying coolant. This design maximizes thermal contact and provides an efficient method of heat removal compared to traditional air-cooled systems. Friction stir welding (FSW) and diffusion bonding have emerged as preferred fabrication techniques, allowing for fine-tuned designs that achieve mechanical integrity and thermal conductivity without introducing filler materials. Radian designs and manufactures custom liquid cold plates using advanced methods including FSW, brazing, and copper tube embedding. Each design is optimized for thermal efficiency, pressure drop, and manufacturability to meet the unique requirements of high-power applications. The range includes increased heat transfer, machined channel cold plates for use with thermal electric coolers and standard cold plates with multi-loop pipe arrangements. EVs, 5G infrastructure, and renewable energy systems are among the fastest-growing sectors adopting liquid cold plate cooling for performance and energy efficiency. In EVs, liquid cooling supports optimal battery temperature and system safety. Liquid cold plates provide the consistency needed to ensure electronics remain within operational limits even in harsh environments, according to Radian. The company’s research indicates that combining liquid cold plate cooling with hybrid air-liquid systems may further expand performance, offering modular solutions that scale with power density requirements. Innovations in microchannel designs and additive manufacturing enable smaller channel diameters and complex flow paths that enhance heat transfer efficiency. Meanwhile, smart monitoring sensors integrated into cooling systems now allow engineers to track temperature, flow rate, and pressure in real time, improving predictive maintenance and system optimization. “Power densities are increasing faster than ever, especially with the rise of AI and its effects on data centers and telecom networks,” said Thierry Sin, CEO of Radian Thermal Products. “Liquid cold plates and liquid cooling solutions have an increasingly important role in maintaining efficiency, reliability, and system longevity.” “Today’s cooling solutions need to be adaptive,” Sin added. “As heat dissipation becomes harder to manage, thermal management systems should become more innovative. Combining liquid cooling with air cooling and two-phase cooling gives engineers new ways to solve complex thermal dissipation problems.” Source: Radian Thermal Products

Samsonite wheels its way to circular luggage

Their suitcases survive a car crash, a piano drop and a crowbar assault. Samsonite commercials from several years ago convey a longtime durability message that fits the company’s recent circularity push. The luggage maker is increasingly making recycled and repairable materials central to its products and emissions goals. “When we ask the luggage and bag consumer, durability is the top choice criteria, but repair and sustainable materials are other important considerations,” Samsonite VP and Global Head of Sustainability Marina Dirks told Trellis. Last year, 40 percent of the company’s net sales included products with recycled content, up from 23 percent in 2022. In September, Samsonite launched what it considers a milestone: mainstream products that incorporate learnings from pilot projects. Components of the Paralux rolling suitcases include 100-percent recycled aluminum pull tubes; half of the hard polypropylene shells from recycled sources; and fully recycled fabrics, zipper tape and inner linings. “Circularity in durable consumer products is an exciting and fast-developing space,” said Steve Diacono, strategic design manager at the Ellen MacArthur Foundation in England. “Many durable products have become almost synonymous with the curbside. We’ve all seen that old suitcase or dirty mattress abandoned on the street. These products still hold value, yet they often end up as waste because disposal is expensive or inconvenient for consumers, and recovery systems remain limited.” Products with long lifespans are ideal for circular design, added Diacono, noting Samsonite’s experiments feeding material from old suitcases into new ones and formulating wheels for easy fixes should they fail. Since 1910 Registered in Luxembourg with U.S. offices in Mansfield, Massachusetts, Samsonite saw $3.6 billion in 2024 sales for its Tumi, American Tourister and other brands, a modest 2.4 percent dip from 2023. The company has been listed on the Hong Kong Stock Exchange since 2011, following numerous twists since its 1910 origins as the Shwayder Trunk Manufacturing Company of Denver. Recycled materials are core to Samsonite’s emissions goals, validated in March by the Science-Based Targets initiative (SBTi). Ninety-five percent of its climate footprint derives from Scope 3. Eighty percent comes from purchased goods and services, which Samsonite aims to slash 52 percent by 2030 over 2022 levels per unit of gross profit. (Its emissions progress is tied to financial performance.) Consulting globally across sourcing, product development, designers, brand and marketing personnel, Dirks’ team found out about future product plans, then explored how to dial up their recycled content. Screen grab from a Samsonite video featuring its Essens capsule collection, which includes plastic recycled from used suitcases. Credit: Samsonite “Our vision is to really use our leadership position to create a more sustainable future for our industry,” she said. Conducting a materiality assessment including third-party suppliers confirmed that approach. Sourcing varies geographically. Initially, for manufacturing in Belgium, the company sourced recycled polypropylene from things like yogurt cups and other household waste. In Asia, it took plastic from recycled laundry machine barrels. Circular evolution The emphasis on circular materials emerged in 2018 with Samsonite’s first “eco collection,” which used recycled plastic bottles in linings and soft casings. Smaller collections, like the Essens Circular suitcases introduced this spring, were partly sourced from material in suitcases returned by consumers. They incorporate plastics derived from restaurant cooking oil. Supplier LyondellBasell provided the “biocircular” material, certified under the International Sustainability and Carbon Certification mass balance approach. Essens also marked Samsonite’s first use of Digital Product Passports, letting consumers scan a QR code to view lifecycle details. Testing and tradeoffs Samsonite tests its products in regional labs. Most suppliers test components, too. The company evaluates each component before assembly: Can it handle high heat and humidity? How about rough handling? Sustainable design must balance durability, repair and innovative materials, according to Dirks, former director of global sustainability at Tiffany & Co. Plastics recycled multiple times can become less durable, unlike aluminum. That’s why outer shells, fabric linings and pull handles have higher recycled content than wheels, which are central to suitcase functionality. “We all know how a piece of luggage might be thrown around by an airline no matter how careful they are,” Dirks said. “It just needs to be able to withstand a lot more than some other applications of recycled materials.” Repair Dirks’ team also considers the tension between long-lasting products and eventual repairs. “If you buy a car, it’s to be expected you service it once a year,” she said. Samsonite consumers already “have that expectation that no matter how durable it is, things happen.” For those cases, Samsonite seeks to simplify repair options through stores, at home and via third-party centers. Paralux owners can replace a busted wheel or pull handle at home, guided by videos using shipped parts. “The only thing you need to replace is a pin,” Dirks said. Shipping small parts rather than whole products further reduces emissions. Diacono noted that steps like these are the kind of progress needed for durable consumer goods. “To unlock real impact, circular business models — such as rental, repair and refurbishment — need to scale,” he said. Other sustainability progress Samsonite continues to use 100 percent renewable energy in its own operations, achieved two years ahead of schedule in 2023. It also surpassed a 15 percent carbon intensity reduction goal for 2025. However, the company has not submitted a net zero goal to the SBTi. Dirks, who reports to CEO Kyle Francis Gendreau, said the company is watching how the SBTI’s standards evolve. However, current sustainability metrics don’t incentivize product durability and other circular practices. “From a target-setting perspective,” Dirks said, “that puts you in a worse place than if you were to design a product that just has a very low carbon footprint, but maybe breaks a year into use.” The post Samsonite wheels its way to circular luggage appeared first on Trellis.

Doosan Robotics wins two CES Innovation Awards 2026

Doosan Robotics has been named a CES Innovation Awards Best of Innovation in the artificial intelligence category and an honoree in the robotics category for its Scan & Go autonomous robotic solution. The awards, presented by the Consumer Technology Association (CTA), recognize outstanding design and engineering across cutting-edge technology products ahead of CES 2026, the world’s most influential tech event, taking place January 6–9 in Las Vegas. The solution is being developed in collaboration with Maple Advanced Robotics Inc. (MARI), a partner company of Doosan Robotics. MARI is a Canada-based innovation company in the field of Robotics and Automation, actively advancing the development and provision of AI-driven robotic platforms. The Scan & Go is an AI-powered autonomous robotic solution that revolutionizes large-scale manufacturing and composite repair. Through cognitive learning with physics-based intelligence and 3D perception, Scan & Go interprets complex geometries in real time and generates optimized tool paths directly from point-cloud data—eliminating the need for CAD modeling, code programming. In addition, this robotic solution autonomously adapts and optimizes motions for high precision, complex work. Mounted on a self-driving forklift, the system autonomously navigates, positions, and operates across large, irregular structures such as aircraft fuselages, wind turbine blades, and architectural façades. It performs sanding, grinding, and inspection tasks with minimal preparation, enabling faster production cycles, reduced labor costs, improved quality, and safer workspaces. Rooted in Doosan Robotics’ human-centered design philosophy, the Scan & Go solution was developed to automate hazardous and labor-intensive composite maintenance where workers face noise, fine dust, repetitive strain, and fall risks. With the highest safety level (PL e, Cat 4), torque-sensing collision detection, and fence-free operation, Scan & Go enables safer, more productive environments—already recognized by leading wind energy manufacturers for improving both quality and safety. Earlier this year, Doosan Robotics announced its strategic transformation into an AI robotic solutions company, focusing on securing future growth engines and strengthening global technological competitiveness. Achieving the Best of Innovation at CES 2026 marks the debut of Doosan’s AI robotic solutions on the world stage, where it has been recognized for exceptional technological excellence and innovation. For more information, visit doosanrobotics.com. The post Doosan Robotics wins two CES Innovation Awards 2026 appeared first on Engineering.com.

When Tesla’s FSD works well, it gets credit. When it doesn’t, you get blamed.

Tesla has engaged in a pattern of taking credit for the successes of its Full Self-Driving (FSD) software, even though the car still relies on an attentive driver, and yet blaming the driver rather than the software whenever things go badly. But new moves towards allowing more distracted driving could make it harder for the company to blame drivers when its software fails. more…

Avery Dennison introduces a new portfolio of tapes, graphics and labels for EV charging stations

Labeling icon Avery Dennison has introduced a new portfolio of pressure-sensitive adhesive (PSA) tapes, graphics, labels and reflective solutions designed for common EV charging station applications. Avery Dennison EV charging station applications include: Gaskets and seals Display mounting Mounting of parts and components Overlay and membrane touch Structural damping Electrical insulation Safety and warning labels Station branding and directional signage Enhancing station, pathway and hazard visibility Avery Dennison PSA materials are available in a variety of options for adhesive formulation, carrier and liner. The company can also collaborate to create custom solutions for specific applications and provide application engineering and technical support to customers worldwide. “There are more EVs on the road than ever, and we want to partner with manufacturers to simplify and speed up the rollout of robust, reliable chargers,” said Danielle Wiltrout, Product Manager General Industrial, Avery Dennison Performance Tapes. “EV charging station manufacturers need solutions that are scalable, durable, easy to apply, and in the instance of tapes offer dielectric strength to expand charging access as quickly and efficiently as possible.” Source: Avery Dennison

Tesla Semi undergoes major redesign as dedicated factory preps for deliveries

Tesla put its all-electric Semi truck through quite a major redesign as its dedicated factory for the vehicle is preparing for initial deliveries to the public starting next year. The Semi has been one of the most anticipated products in the Tesla lineup due to the disruption it could cause in the trucking industry. It has already been in numerous pilot programs for some pretty large companies over the past couple of years, PepsiCo. being one of them, and it is moving toward first deliveries to other companies sometime in 2026. Yesterday at the 2025 Annual Shareholder Meeting, Tesla unveiled its new Semi design, which underwent a pretty significant facelift to match the aesthetic and vibe of the other vehicles in the company’s lineup. Additionally, Tesla announced some other improvements, including changes to efficiency, and some other changes that we did not get details on yet. The first change was to the design of the Semi, as Tesla adopted its blade-like light bar for the Class 8 truck, similar to the one that is used on the new Model Y and the Cybertruck: There also appear to be a handful of design changes that help with aerodynamics, as its efficiency has increased to 1.7 kWh per mile. Tesla also said it has an increased payload capability, which will help companies to haul more goods per trip. All of these changes come as the company’s Semi Factory, which is located on the same property as its Gigafactory in Reno, Nevada, is just finishing up. In late October, it was shown that the Semi facility is nearly complete, based on recent drone imagery from factory observer HinrichsZane on X: Tesla Semi factory looks nearly complete The factory will be capable of producing about 50,000 Tesla Semi units annually when it is completely ramped. The company has major plans to help get the Semi in more fleets across the United States. Other entities are also working to develop a charging corridor for electric Class 8 trucks. The State of California was awarded $102 million to develop a charging corridor that spans from Washington to Southern California. Another corridor is being developed that spans from Southern California to Texas, and 49 applicants won $636 million from the Department of Transportation for it. Tesla requested funding for it, but was denied. The Semi has been a staple in several companies’ fleets over the past few years, most notably that of Frito-Lay and PepsiCo., who have reported positive experiences thus far. Musk said last year that the Semi had “ridiculous demand.” The post Tesla Semi undergoes major redesign as dedicated factory preps for deliveries appeared first on TESLARATI.

Tesla launches another new Model Y trim at a bargain price with massive range

Tesla has launched yet another new Model Y trim level, but this time it is in China, and it is at a bargain price. It also has an insane range rating. On Friday, Tesla launched the new Model Y Long Range Rear-Wheel-Drive in China, priced at 288,500 yuan ($40,500), an incredible deal considering it is not a stripped-down version of the vehicle like the Model Y Standard. Tesla’s new China-launched Model Y LR RWD offers 821 km (510 miles) CLTC range with 78.4 kWh CATL battery, beating AWD’s 750 km. At 288,500 yuan ($40,500 USD), it fits between base RWD (593 km, 263,500 yuan) and AWD (313,500 yuan) for affordable long-range EVs. CLTC… pic.twitter.com/ZOoelziJ8T — TESLARATI (@Teslarati) November 8, 2025 It is the second most-affordable Model Y trim level in China, trailing the base Rear-Wheel-Drive and coming in under the All-Wheel-Drive. The big appeal with this new Model Y trim is obviously its price, but its range rating is also one of the best we’ve seen. Rated at 821 kilometers on the CLTC scale, it converts to 510 miles. It uses a 78.4 kWh CATL battery. Converted to real-world range, however, that 821-kilometer range rated by the CLTC actually is equivalent to about 357 miles on the EPA scale, which is still a very respectable number and comes in at a higher range than the Long Range All-Wheel-Drive configuration that is available in the U.S. Tesla has truly brought a wide variety of Model Y trims to the Chinese market, including a new Model Y L configuration that features a slightly longer wheelbase, as well as additional interior features like extended thigh legrests and captain’s chairs with armrests. It is unclear whether Tesla will bring a Premium Rear-Wheel-Drive option of the Model Y to the U.S., especially as it has already rolled out four configurations of the all-electric crossover in the market. With the new Standard offerings, Tesla will likely keep its lineup as simple as possible. However, the company has hinted that there is a slim possibility the Model Y L could come to the U.S. sometime late next year, but CEO Elon Musk said that it is not a guarantee. Tesla is more concerned with self-driving efforts in the U.S., and despite calls from customers for larger vehicles, it does not seem concerned with making them available, at least not for now. The post Tesla launches another new Model Y trim at a bargain price with massive range appeared first on TESLARATI.

Tesla confirms Robotaxi is heading to five new cities in the U.S.

Tesla Robotaxi will hit five new cities in the United States in the coming months, the company confirmed. After launching in Austin, Texas, in late June and the Bay Area of California just a few weeks later, Tesla has been attempting to expand its Robotaxi suite to new states and cities in the U.S., and even outside of the country. The Robotaxi suite is a ride-hailing service Tesla offers, but the details of it change with each jurisdiction, as regulations vary. For example, in Austin, Tesla can operate the Robotaxi suite without anyone in the driver’s seat, as long as the vehicle does not enter a freeway. Credit: Tesla In the Bay Area, a Safety Monitor rides in the driver’s seat, essentially acting as the vehicle operator with Full Self-Driving controlling the car. The local regulations and how Tesla handles them will continue to be a relevant part of the discussion, especially as the company aims to expand the Robotaxi program to different areas. This has been a primary focus of the company for several months, especially within the United States. CEO Elon Musk said that Tesla was aiming to launch Robotaxi in Nevada, Arizona, and Florida. However, the company detailed five specific cities where it will launch Robotaxi next during the Annual Shareholder Meeting on Thursday. Tesla will launch Robotaxi in Las Vegas, Phoenix, Dallas, Houston, and Miami next, broadening its Service Area for the suite to more major cities across the U.S. It has said it plans to offer the service to half of the U.S. population by the end of the year, but it does not seem as if it will expand to more than a handful of cities this year, which is still tremendous progress, all things considered. As far as autonomy is concerned, Tesla has always had lofty expectations and has made some even loftier statements. At the Shareholder Meeting, Musk said that the company would likely be able to enable vehicle owners to text while the vehicle drives, alleviating them from potentially having some of the responsibility they have behind the wheel. Tesla says texting and driving capability is coming ‘in a month or two’ It is not confirmed that Tesla will roll this out in the next few months, but Musk said there is a possibility. The post Tesla confirms Robotaxi is heading to five new cities in the U.S. appeared first on TESLARATI.

Tesla says texting and driving capability is coming ‘in a month or two’

Tesla CEO Elon Musk said that within the next month or two, the company will be able to open the ability for people to text and drive because its Full Self-Driving suite will be robust enough to allow drivers to take their attention away from the road. In its current state, Tesla Full Self-Driving is a supervised driver assistance suite that requires the vehicle operator to maintain control of the vehicle and pay attention to the road surroundings. However, the company has been aiming to release a fully autonomous version of the Full Self-Driving suite for years, teasing its future potential and aiming to release a Level 5 suite as soon as possible. CEO Elon Musk believes the company is on the cusp of something drastic, according to what he said at yesterday’s Annual Shareholder Meeting. One thing Musk hinted at was that the company should be able to allow those sitting in the driver’s seat of their cars to text and drive “in the next month or two,” as long as the statistics look good. He said: “In the next month or two, we’re going to look at the safety statistics, but we’re going to allow you to text and drive, essentially.” The company recently transitioned to its v14 Full Self-Driving suite, which is its most robust to date, and recently expanded to Cybertruck, completing its rollout across the vehicle lineup. Currently, Tesla is running v14.1.5, and when major improvements are made, that second number will increase, meaning v14.2 will be the next substantial improvement. Musk said that v14.3 will be when you can “pretty much fall asleep and wake up at your destination.” Elon Musk says Tesla Full Self-Driving v14.3 will be when you can “pretty much fall asleep and wake up at your destination.” We are on v14.1 currently pic.twitter.com/KMkWh5Qa7T — TESLARATI (@Teslarati) November 6, 2025 We’ve heard a considerable amount of similar statements in the past, and Tesla owners have been conditioned to take some of these timeframes with autonomous driving with a grain of salt. However, with the upgrades in FSD over the past few months, especially with the rollout of Robotaxi in Austin, which does not utilize anyone in the driver’s seat for local roads, it does not seem as if autonomy is that far off for Tesla. The post Tesla says texting and driving capability is coming ‘in a month or two’ appeared first on TESLARATI.

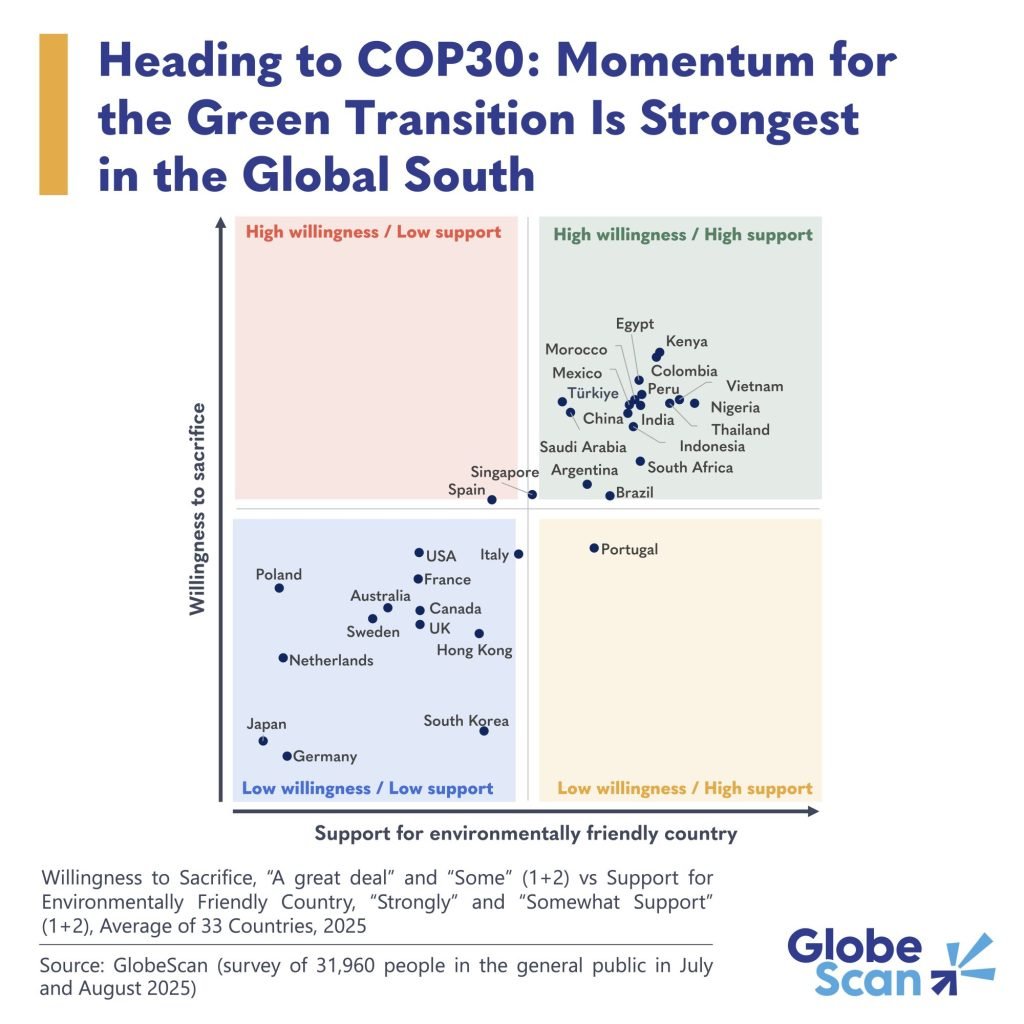

Green transition momentum strongest in Global South

Building on sentiments from how people engage emotionally with climate action, research shows people in the Global South express strong support for environmentally-friendly development and a willingness to make personal sacrifices to achieve it. Countries such as Kenya, Colombia, Peru, Vietnam, Nigeria, India, Indonesia, Thailand, South Africa and Brazil stand out for their strong support for a greener future and high willingness to make sacrifices to achieve it, according to survey by Trellis data partner GlobeScan. In contrast, enthusiasm for green progress often stops short of personal trade-offs in the Global North, reflecting a more cautious, comfort-driven approach. Many countries in the Global North, including the U.S, U.K., France, Germany, Japan and Australia, fall into the quadrant of lower support and lower willingness to sacrifice, signaling a need for different engagement strategies. What this means Accelerating the global green transition requires recognizing regional dynamics. Tailored strategies that reflect local motivations and realities will be essential to drive meaningful climate action worldwide. In the Global North, the challenge is to make sustainable choices easier, more affordable and more aspirational. In the Global South, there is clear momentum for ambitious change and a readiness to act. The strong correlation between support and willingness to sacrifice in the Global South signals that these countries have the social foundation needed to drive progress if other conditions (economical, political, structural) permit. In the words of former UN Climate Change Executive Secretary Christiana Figueres: “The world is no longer waiting for Washington. This time the Global South is leading the way.” Based on a survey of more than 31,000 people conducted July — August 2025. The post Green transition momentum strongest in Global South appeared first on Trellis.

ARBOR earns Taiwan Excellence Award for edge AI systems

ARBOR Technology Corp. has received the Taiwan Excellence Award 2026 for three flagship solutions – FPC-5211 series, IEC-3714, and IEC-G510. This recognition validates ARBOR’s exceptional innovation capabilities in compact, rugged, energy-efficient, and AI-communication ready – that represents ARBOR’s technology leadership globally. ARBOR Technology Wins Taiwan Excellence Award with High-Performance Edge AI Computing Solutions. ARBOR FPC-5211 series: ESG high-performance fanless edge computing system FPC-5211 series, winner of the Embedded World 2025 Best-in-Show award, redefines fanless edge AI computing. Built on the philosophy of “Zero-Carbon Smart Manufacturing, Edge Computing Excellence,” it combines Intel Raptor Lake processors with NVIDIA RTX-2000A GPUs in a compact, fanless design. The system cuts energy use by 70%, triples service life, and delivers military-grade reliability for smart manufacturing, AOI inspection, and smart healthcare applications. ARBOR IEC-3714: AI edge computing for smart retail solution IEC-3714 is a compact AI edge computing digital signage system delivering 34 TOPS of AI performance with four-channel 4K synchronous output. Powered by the Intel® Core Ultra processor, it runs four OpenVINO AI models—face, age/gender, expression, and object recognition—enabling real-time, AI-driven advertising, passenger flow analytics, and cashierless retail. Its ultra-compact 115.4×107.6×37mm design reduces equipment costs by 60% and operating expenses by 40%, setting a new benchmark for next-generation AI signage. ARBOR IEC-G510: ultra-slim AI smart digital signage player system IEC-G510 is the industry’s first ultra-thin player built on the MediaTek Genio 510 platform with integrated AI acceleration. Measuring just 20mm thick, it features an APU neural network processor for real-time facial and emotional recognition while cutting material costs by 35% versus x86 systems. With advanced thermal design and compact integration, it delivers high-performance, low-power AI computing ideal for smart retail and interactive advertising applications. Winning the Taiwan Excellence Award affirms ARBOR’s innovation and showcases Taiwan’s strength in smart manufacturing. ARBOR will continue to invest in AI and edge computing research and development (R&D), empowering global customers to confidently drive digital transformation. For more information, visit arbor-technology.com. The post ARBOR earns Taiwan Excellence Award for edge AI systems appeared first on Engineering.com.