Elon Musk confirms Tesla AI6 chip is Project Dojo’s successor

Earlier this week, reports emerged stating that Tesla has stepped back from its Project Dojo initiative. While the reports were initially framed as a negative development for the electric vehicle maker’s autonomous driving efforts, CEO Elon Musk later noted on X that Tesla was indeed halting its Dojo initiative. Elon Musk’s Confirmation As per Musk, Tesla was shuttering Project Dojo because it does not make sense for the company to divide its resources and scale two different AI chip designs. Dojo, after all, is designed to train the company’s autonomous driving program, and thus, it would not be rolled out to Tesla’s consumer products. In a series of posts on X, Musk stated that it would make sense to just use Tesla’s AI5/AI6 to train its FSD and Autopilot systems. “In a supercomputer cluster, it would make sense to put many AI5/AI6 chips on a board, whether for inference or training, simply to reduce network cabling complexity & cost by a few orders of magnitude,” Musk said. Tesla’s AI5 and AI6 chips are expected to be rolled out to the company’s consumer products, from Optimus to the Cybercab to the next-generation Roadster. — Elon Musk (@elonmusk) August 8, 2025 AI6 is Dojo’s Successor What was particularly interesting about Musk’s comment was his mention of using AI5/AI6 chips for training. As per Musk, this strategy could be seen as “Dojo 3” in a way, since the performance of Tesla’s AI5 and AI6 chips is already notable. Musk’s comment about using AI6 chips for training caught the eye of many, including Apple and Rivian alumnus Phil Beisel, who noted that “AI6 is now Dojo.” “Dojo is Tesla’s AI training supercomputer, built around a custom chip known as the D1. The D1 and AI5/AI6 share many core design elements, particularly the math operations used in neural networks (e.g., matrix multiplication) and highly parallel processing. “Dojo had a unique feature: chips arranged in a 5×5 grid using a system-on-wafer design, with etched interconnects enabling high-speed data transfer. In a sense, Dojo will live on as the generalized AI6. Going forward, all efforts will focus on AI6,” the tech veteran wrote in a post on X. Elon Musk confirmed the Apple alumnus’ musings, with the CEO responding with a “bullseye” emoji. Musk is evidently excited for Tesla’s AI6 chip, which is expected to produced by Samsung’s upcoming Texas fabrication facility. In a post on X, Musk stated that he would personally be walking Samsung’s line to accelerate the output of Tesla’s AI6 computers. The post Elon Musk confirms Tesla AI6 chip is Project Dojo’s successor appeared first on TESLARATI.

Tesla Model 3 filings in China show interesting hardware addition

Tesla Model 3 filings in China are showing the vehicle could get a very interesting hardware addition, one that was not included on the “Highland” update when it rolled out to customers a year and a half ago. The Model 3 Highland is Tesla’s updated version of the all-electric sedan, and was launched across the world in early 2024. It featured a variety of updates, including new exterior and interior designs. However, there were a few things missing from the update that surprised Tesla fans because they were included on other cars. One of them was the lack of a front bumper camera, a hardware piece that was included on other vehicles within the company’s lineup, including the Model Y Juniper, an updated version of the all-electric crossover that launched earlier this year. Now, it seems Tesla is preparing to implement that front camera on the Model 3, as new filings with China’s Ministry of Industry and Information Technology (MIIT) showed the car with the addition: Tesla will soon add a front bumper camera to the Model 3! The images confirming this upgrade were leaked on the official website of China’s Ministry of Industry and Information Technology (MIIT). H/t @kas12323 pic.twitter.com/ieRv9wiwOK — The Tesla Newswire (@TeslaNewswire) August 8, 2025 The front bumper camera is a small but powerful addition to Tesla vehicles. It not only enhances visibility for simple tasks like parking, helping avoid things like curbs, but it also helps provide a wider field of view directly in front of the car. It is also a crucial part of the Full Self-Driving and Autopilot suites, helping provide yet another angle of vision for the vehicle as Tesla makes its suite more robust. It is already improving through software upgrades and data collection, but it could always use additional hardware to enhance accuracy. A Model 3 Highland test mule was spotted near Boston, Massachusetts, back in May with a variety of additional cameras equipped. Some believed this was a vehicle that was assisting with collecting training data. Tesla is testing a Model 3 with some mysterious cameras in the U.S. However, it could be a sign of Tesla planning to add this piece of hardware to a slightly updated version of the new Model 3 that could come to production in various markets in the near future. The post Tesla Model 3 filings in China show interesting hardware addition appeared first on TESLARATI.

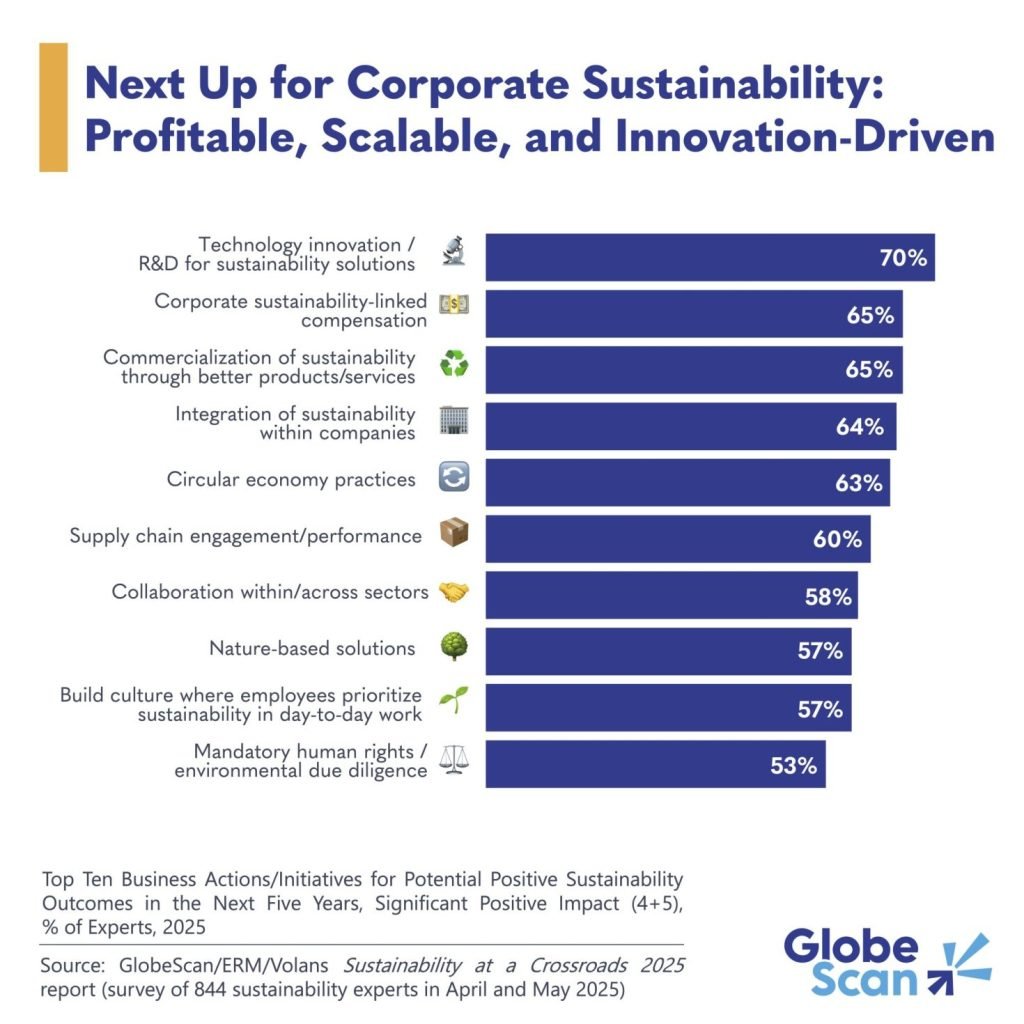

5 corporate actions that will make the most impact by 2030

Sometimes it’s hard to tell what corporate actions are really making a difference. But according to a survey of more than 800 sustainability experts, these actions are the most impactful over the next five years: Tech innovation and R&D (70 percent) Corporate sustainability-linked compensation (65 percent) Commercialization of sustainability via products and services (65 percent) Actions such as integrating sustainability within companies (64 percent) and adopting circular economy practices (63 percent) also rank in the top 10 in a list of 23 potential ways that business can drive positive sustainability outcomes, according to the survey by Trellis data partner GlobeScan in collaboration with ERM and Volans. What this means Experts are shifting focus from compliance and culture-building toward systemic, performance-driven strategies. The emphasis on technology and commercialization as key levers reflects a growing consensus that sustainability must be profitable, scalable and embedded — and not treated as peripheral. At the same time, experts are calling on businesses to act as systems integrators, aligning across stakeholders and domains. They also want businesses to anticipate the convergence of expectations around innovation, circularity and supply chains, lead with transparency and embed sustainability into core strategy rather than approaching it as a separate or siloed initiative. Based on a survey of 844 sustainability practitioners across 72 countries conducted April-May 2025. The post 5 corporate actions that will make the most impact by 2030 appeared first on Trellis.

Toyota boosts production with Stratasys additive manufacturing

Stratasys Ltd. announced that Toyota’s production engineering group is working with Stratasys to integrate 3D printing technology into its manufacturing process. The collaboration enables the production of tools, fixtures, and jigs from initial concept to prototype within one day. Over its more than 10-year partnership with Stratasys, Toyota has used industrial-grade 3D printers and materials suited for factory conditions. These polymers help reduce dependence on external suppliers and long lead times, enabling engineering teams to make design changes and respond to production needs more quickly. Toyota is currently using the Stratasys F3300, F900, Origin One, F770, Neo800, H350, F370, J850, and Fortus 450mc printers to produce robust factory tooling, end-use parts, and functional prototypes throughout its North American facilities. See how Toyota is using additive manufacturing in this video. An end of arm tool 3D printed at the Toyota ADD Lab using the Stratasys F900 3D printer and ASA material. By integrating Stratasys industrial 3D printing solutions across its North American operations, Toyota can transform ideas into durable, customized tools that support workflows, enhance worker safety, and withstand wear and tear. Much of this work is powered by the Toyota Add Lab, the company’s in-house additive manufacturing center that was opened in January 2023 and dedicated to accelerating R&D and factory innovation. The collaboration reflects Stratasys’ broader commitment to helping automotive leaders transform their manufacturing workflows with scalable, cost-effective additive solutions that drive innovation. From jigs and fixtures to ergonomic aids and complex assembly tools, additive manufacturing is helping Toyota team members solve production challenges with unprecedented speed and flexibility. Toyota engineers used 3D printing at the Add Lab to redesign a door assembly fixture, producing a lighter, more ergonomic tool on-site in a few days. They also developed a custom window alignment jig that allowed the work to be completed by one person instead of several, improving safety and efficiency. To learn more, visit stratasys.com. The post Toyota boosts production with Stratasys additive manufacturing appeared first on Engineering.com.

The oddly personal truth about ADAS: self-driving cars are like running shoes

There you are, motoring along in your Volvo XC90 PHEV with the Pilot Assist engaged alongside a big 18-wheeler at a comfortable 70 mph cruise when the interstate starts to slowly sweep left. From the drivers’ seat, that semi on your right looks awfully close. As the steering wheel turns itself in your hand, you start to wonder if that truck’s a bit too close. The car isn’t doing anything wrong, but it’s too close for your comfort and you give the wheel a little nudge to hug the inside of the lane just a bit more. These deeply personal preferences are tough to quantify, and highlight a simple fact about Advanced Driver Assistance Systems (ADAS) that the industry at-large hasn’t yet to come to terms with: when it comes to self-driving cars, one size does not fit all. more…

Webinar: Leveraging Vector and CSM measurement technology throughout EV development

Join this webinar at our September Virtual Conference on EV Engineering, presented by CSM, where we will introduce the various measurement technologies available from Vector and CSM, and discuss when to use which tools for your software testing, ECU development, calibration and validation tasks. Join us to learn about systems like VT, VX, VIO and CSM’s ruggedized measurement modules—what each is for, and even how to use them together. September 17, 2025, 11:45 am EDTRegister now—it’s free! See the complete session list for the Virtual Conference on EV Engineering here. Broadcast live from September 15 to 18, 2025, the conference content will encompass the entire EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

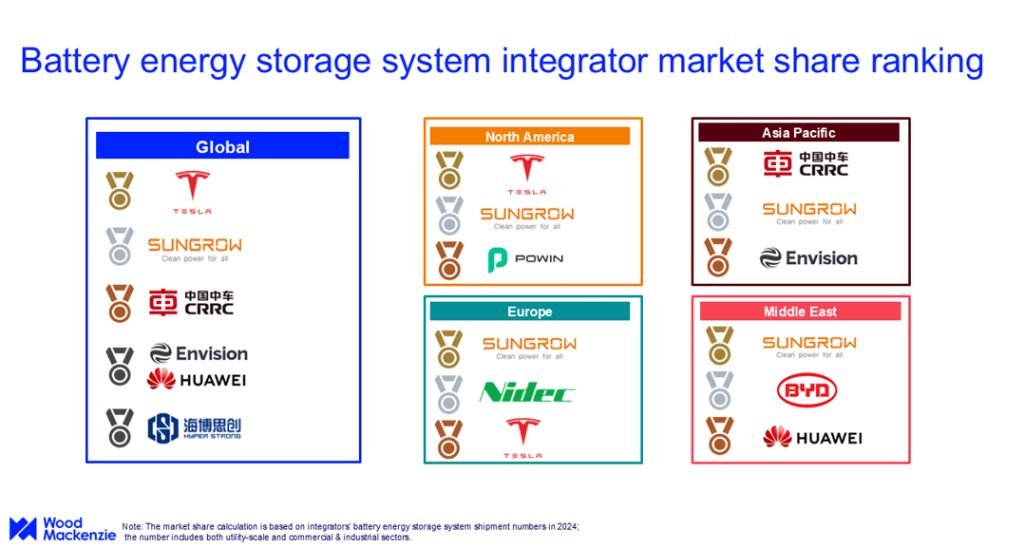

Tesla Energy is the world’s top global battery storage system provider again

Tesla Energy held its top position in the global battery energy storage system (BESS) integrator market for the second consecutive year, capturing 15% of global market share in 2024, as per Wood Mackenzie’s latest rankings. Tesla Energy’s lead, however, is shrinking, as Chinese competitors like Sungrow are steadily increasing their global footprint, particularly in European markets. Tesla Energy dominates in North America, but its lead is narrowing globally Tesla Energy retained its leadership in the North American market with a commanding 39% share in 2024. Sungrow, though still ranked second in the region, saw its share drop from 17% to 10%. Powin took third place, even if the company itself filed for bankruptcy earlier this year, as noted in a Solar Power World report. On the global stage, Tesla Energy’s lead over Sungrow shrank from four points in 2023 to just one in 2024, indicating intensifying competition. Chinese firm CRRC came in third worldwide with an 8% share. Wood Mackenzie ranked vendors based on MWh shipments with recognized revenue in 2024. According to analyst Kevin Shang, “Competition among established BESS integrators remains incredibly intense. Seven of the top 10 vendors last year struggled to expand their market share, remaining either unchanged or declining.” Chinese integrators surge in Europe, falter in U.S. China’s influence on the BESS market continues to grow, with seven of the global top 10 BESS integrators now headquartered in the country. Chinese companies saw a 67% year-over-year increase in European market share, and four of the top 10 BESS vendors in Europe are now based in China. In contrast, Chinese companies’ market share in North America dropped more than 30%, from 23% to 16% amid Tesla Energy’s momentum and the Trump administration’s policies. Wood Mackenzie noted that success in the global BESS space will hinge on companies’ ability to adapt to divergent regulations and geopolitical headwinds. “The global BESS integrator landscape is becoming increasingly complex, with regional trade policies and geopolitical tensions reshaping competitive dynamics,” Shang noted, pointing to Tesla’s maintained lead and the rapid ascent of Chinese rivals as signs of a shifting industry balance. “While Tesla maintains its global leadership, the rapid rise of Chinese integrators in Europe and their dominance in emerging markets like the Middle East signals a fundamental shift in the industry. Success will increasingly depend on companies’ ability to navigate diverse regulatory environments, adapt to local market requirements, and maintain competitive cost structures across multiple regions,” the analyst added. The post Tesla Energy is the world’s top global battery storage system provider again appeared first on TESLARATI.

Tesla expands Robotaxi program in Austin to new riders

Tesla is expanding its Robotaxi program in Austin, Texas, as several people have received invitations to participate and take rides. Tesla first launched the Robotaxi platform on June 22. It invited a handful of people to participate in the first-ever public rides. We were lucky enough to get an invitation, and our permissions have been expanded in the Bay Area pilot program as well. The group was small and consisted of big names in the Tesla community. It expanded and is continuing to offer these exclusive invitations to notable members of the Tesla community. There have been fewer than five subsequent invitations after the first group’s were sent in late June: I’m so stoked!! LFG @Tesla @Tesla_AI @robotaxi @elonmusk pic.twitter.com/F4chRhMjc9 — Arash (@MinimalDuck) August 7, 2025 I finally got it, guys!! @robotaxi early access invite Wait, does it mean I have to be 65 or wait another 65 years? pic.twitter.com/yAVPHXISY6 — JeebsTX (@JeebsTX) August 7, 2025 Tesla has been expanding both the rider group and the geofence in Austin slowly, making sure to prioritize safety and avoid any major events with the early rollout. Tesla’s new Robotaxi geofence shape is an FU by Elon Musk to the competition “We are being very cautious. We do not want to take any chances, so we are going to go cautiously. But the service areas and the number of vehicles in operation will increase at a hyper-exponential rate,” CEO Elon Musk said during the Q2 Earnings Call. Eventually, the Robotaxi platform will not require an invite, and it will operate without geofences. Musk believes Tesla can get there within three or six months, and plans to have at least half of the U.S. population with access to a Robotaxi by the end of the year: Tesla plans to offer driverless Robotaxi rides to half the U.S. population by the end of the year, Musk says — TESLARATI (@Teslarati) July 23, 2025 “I think we will probably have autonomous ride-hailing in probably half the population of the U.S. by the end of the year. That’s at least our goal, subject to regulatory approvals. I think we will technically be able to do it. Assuming we have regulatory approvals, it’s probably addressing half the population of the U.S. by the end of the year.” Tesla plans to have regulatory approval in Nevada, Arizona, and Florida sooner than in other states. The post Tesla expands Robotaxi program in Austin to new riders appeared first on TESLARATI.

Apple announces $100B American Manufacturing Program

Production of the cover glass for iPhone and Apple Watch in Corning’s Harrodsburg, Kentucky, manufacturing facility. (Image: Apple) Apple has announced a new $100 billion commitment, adding to its U.S. investment that now totals $600 billion over the next four years. Today’s announcement includes the tech giant’s American Manufacturing Program (AMP), which promises more of Apple’s supply chain and advanced manufacturing will take place in the U.S. The AMP will also incentivize global companies to manufacture even more critical components in the United States. “This includes new and expanded work with 10 companies across America. They produce components that are used in Apple products sold all over the world, and we’re grateful to the President for his support,” said Apple’s CEO Tim Cook, in a press release. As part of the program, Apple plans to directly hire 20,000 people in the U.S., mostly focused on R&D, silicon engineering, software development, and AI and machine learning. Apple American Manufacturing Program The first AMP partners announced as part of the program include Corning, Coherent, GlobalWafers America (GWA), Applied Materials, Texas Instruments (TI), Samsung, GlobalFoundries, Amkor, and Broadcom. The American Manufacturing Program will help fund a major expansion of Apple’s long-standing partnership with Corning, bringing advanced smartphone glass production to a factory in Harrodsburg, Kentucky. The two companies will also open a new Apple-Corning Innovation Center in Kentucky. Apple has also entered into a new multiyear agreement with Coherent, a longstanding partner that produces the VCSEL lasers that enable features including Face ID at Coherent’s Sherman, Texas, facility. In July, Apple also committed to buying American-made rare earth magnets developed by MP Materials, the only fully integrated rare earth producer in the United States, significantly expanding their flagship Independence facility in Fort Worth, Texas. The two companies will also establish a cutting-edge rare earth recycling line in Mountain Pass, California. End-to-end American silicon supply chain Apple says its U.S. silicon supply chain is on track to produce more than 19 billion chips for Apple products in 2025. That includes TSMC in Arizona, which is producing tens of millions of chips for Apple using one of the most advanced process technologies in America. “We’re committed to supporting U.S. suppliers involved in every key stage of the chip-making process, from the earliest stages of research and development to final fabrication and packaging,” said Sabih Khan, Apple’s chief operating officer. “We want America to lead in this critical industry, and we’re expanding our efforts to grow a silicon manufacturing ecosystem that will benefit innovators across America.” Apple is partnering with GlobalWafers America in Sherman, Texas, to produce advanced wafers for use in U.S.-based semiconductor fabs for the first time. American chip fabs like TSMC in Phoenix, Arizona, and Texas Instruments in Sherman, Texas, will use GWA’s 300mm wafers to produce chips for iPhone and iPad devices sold in the U.S. and around the world. GWA uses silicon from U.S. sources, including from Corning’s Hemlock Semiconductor. Apple is also partnering directly with Applied Materials to boost the production of semiconductor manufacturing equipment in the U.S. The Applied site in Austin, Texas, is a pivotal hub for manufacturing cutting-edge chip equipment. Another aspect of Apple’s AMP is a new commitment with Texas Instruments (TI), which will support additional tool installations at its facility in Lehi, Utah, and a new facility in Sherman, Texas. These facilities are home to TI’s most advanced process technologies and use American-made chip manufacturing equipment from Applied Materials’ factory in Austin, as well as advanced silicon wafers from GlobalWafers America. Apple is also working with Samsung at its fab in Austin, Texas, to launch an innovative new technology for making chips. GlobalFoundries and Apple have also entered an agreement to bring more semiconductor manufacturing to the United States, focused on manufacturing cutting-edge wireless technologies and advanced power management, critical technologies that enable longer battery life and enhanced connectivity in Apple devices. The partnership will bring new capabilities, jobs, and technology to the GlobalFoundries semiconductor facility in Malta, New York. Packaging is the final critical step in manufacturing silicon chips. Apple is investing in Amkor’s new advanced chip packaging and test facility in Arizona and will be its first and customer. This facility will package and test Apple silicon manufactured at the nearby TSMC fab, and create chips used in iPhone devices shipped around the world. Apple is also working with Broadcom and GlobalFoundries to develop and manufacture additional cellular semiconductor components in the U.S. New and expanded facilities Earlier this year, construction began in Houston on the new factory supporting production of advanced Apple servers, and in July, the facility produced its first test unit. The 250,000-square-foot server manufacturing facility is slated to begin mass production in 2026. Previously manufactured outside the U.S., the servers from Houston will play a key role in powering Apple Intelligence and are the foundation of Private Cloud Compute, which combines powerful AI processing with advanced security architecture for AI cloud computing. In Detroit, registration is now open for the new Apple Manufacturing Academy, which was announced in February and is set to open on August 19. The academy will offer consultations and courses to small and medium-sized business on how they can implement advanced manufacturing and AI into their manufacturing programs. The post Apple announces $100B American Manufacturing Program appeared first on Engineering.com.

Bluetti’s new Elite 30 V2 288Wh station gets first savings starting from $199, Segway F3 smart eKickScooter $750, NIU e-scooter sale, more

Headlining today’s Green Deals is the first discount hitting Bluetti’s new Elite 30 V2 Portable Power Station, which also has an additional solar bundle offer starting from $199. We also spotted the first post-tariff discount from Segway on its new Ninebot F3 Electric KickScooter to $750, as well as NIU’s Fan-tastic Day Sale that is taking up to 42% off its KQi lineup of scooters, including the KQi 300X All-Terrain Suspension Electric Scooter that is back at the best price of 2025 for $750, among others. We also have a new low price on Greenworks’ 82V Commercial 20-inch Cordless Chainsaw kit and a one-day-only discount on Worx’s 12A 7.5-inch Edger/Trencher, and more waiting for you below. Plus, all the hangover savings are at the bottom of the page, like yesterday’s Anker SOLIX Summer Power Sale offers, Ride1Up’s increased e-bike savings, and more. Head below for other New Green Deals we’ve found today and, of course, Electrek’s best EV buying and leasing deals. Also, check out the new Electrek Tesla Shop for the best deals on Tesla accessories. more…

Forge Nano develops 100% US-sourced lithium-ion cells for Department of Defense

Forge Nano has announced the development of an 18650-format lithium-ion battery cell intended for testing by the US Department of Defense, comprised entirely of materials sourced within the United States. According to Forge Nano, this cylindrical cell is designed for high capacity and energy density and must meet US Department of Defense requirements for cycle life and operating temperature range. The company says it has vetted numerous components from US suppliers for use in the 18650 cell. Production is underway at Forge Nano’s facility in Thornton, Colorado, on a manufacturing line with a capacity of 10 megawatt-hours per year. Forge Nano intends to deliver the US-sourced lithium-ion cells to the Department of Defense for evaluation in 2025. The cell features Forge Nano’s proprietary Atomic Armor surface coatings, which it claims enhance battery durability and performance. The company has not disclosed further technical specifications or chemistry details in the announcement. “In today’s environment of rising tariffs and global instability, producing a 100% US-sourced lithium-ion cell isn’t just a strategic advantage—it’s a national security imperative,” said Paul Lichty, CEO of Forge Nano. “For the Department of Defense, having a secure, domestic supply of advanced battery technology ensures mission readiness, supply chain resilience, and energy independence in the face of growing international uncertainty.” Source: Forge Nano

Tesla Model Y L spotted testing in China as pricing estimates emerge

The Tesla Model Y L’s details have not been fully released yet, but the vehicle is already sparking a lot of interest in the EV sector. Despite being just an extended wheelbase version of Tesla’s best-selling car, after all, the Model Y L has the potential to become the company’s first true mass market family hauler. Recent Model Y L Sightings Sightings of the upcoming extended wheelbase Model Y variant were shared on social media platforms such as X. As noted by X user @tcmesla, one of Tesla’s Model Y L prototypes was recently photographed as it was undergoing road tests in Xinjiang, China. Similar to Tesla’s other yet-to-be-released vehicles, the Model Y L’s front and rear were covered up during the sighting. One big sign that the vehicle was a Model Y L was its wheels, which were identical to the wheels in the vehicle shown in the China Ministry of Industry and Information Technology’s (MIIT) new regulatory catalog. The new wheels are quite eye-catching, with their apparent star-inspired pattern. $TSLA Six-seater Tesla Model Y L was spotted undergoing testing in the beautiful Xinjiang, China pic.twitter.com/vSxQqx7vqU — TCMesla (@TCMesla) August 6, 2025 Tesla has not indicated when the Model Y L will be released, though speculations are high that the vehicle will be rolled out in China sometime this Q3 2025. After this, the Model Y L is also speculated to be released in other territories. Pricing Speculations Tesla has been very quiet about the Model Y L’s price, though estimates from industry watchers have pointed to a potential price of about RMB 400,000 (about $56,000). If this price were to be accurate, it would suggest that the Model Y L could be about 28% more expensive than the regular Model Y. The 6-seater Tesla Model Y L is rumored to be priced at ~¥400,000 / ~$55,600 in China!If true, it would mean: A 28% increase compared to the Model Y Long Range AWD ~$62,000 in the US ~€67,000 in Europe pic.twitter.com/3xZcS4OeMD — The Tesla Newswire (@TeslaNewswire) August 6, 2025 This could mean that the vehicle may be priced at about $62,000 in the United States, and about €67,000 in Europe. This is quite steep, and it would likely position the Model Y L against more premium rivals in the same price range. Provided that Tesla prices the vehicle competitively, however, the Model Y may have a real shot at becoming a strong seller for the EV maker. The post Tesla Model Y L spotted testing in China as pricing estimates emerge appeared first on TESLARATI.

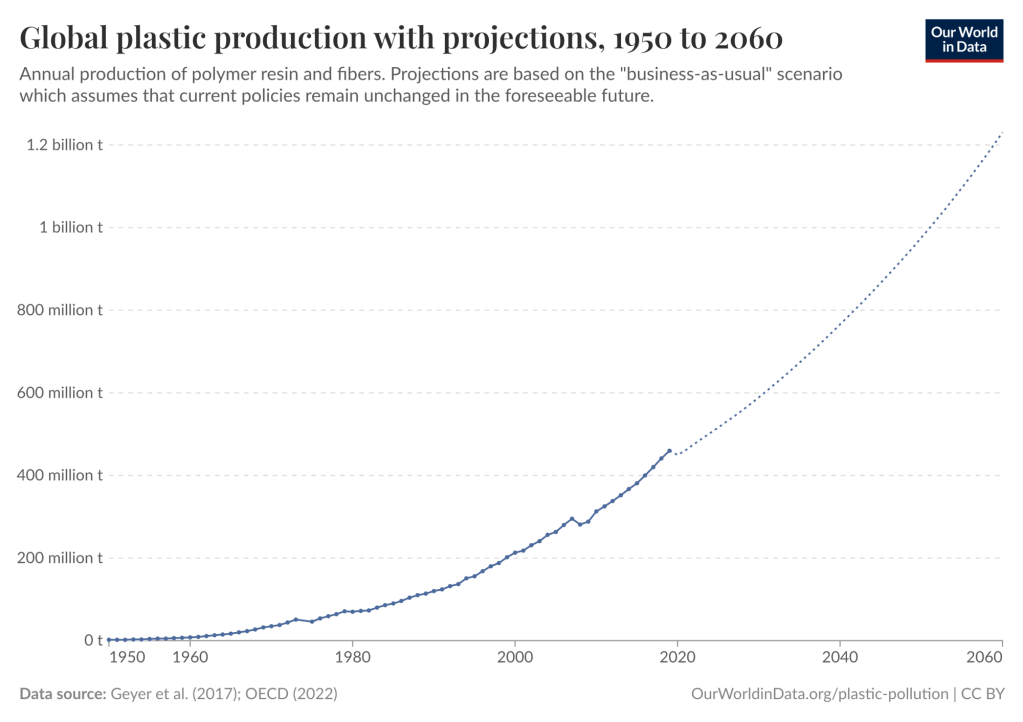

As plastics treaty talks enter the final round, here’s what to expect

The plastics treaty talks that convened on August 5 in Geneva look like the last chance to deliver a meaningful global deal to stem the tide of plastic that is infiltrating our bodies, overwhelming our landfills and devastating our oceans. If successful, it would be the world’s first coordinated legal framework for tackling plastic pollution at scale. If not? Well, read on. The background Launched in 2022 by the U.N. Environment Assembly, the talks seek a legally binding global treaty to end plastic pollution. The goal is to address plastics across their full life cycle — from design and production to use and disposal. Negotiators have met five times so far, most recently in Busan, South Korea, in December. That session, meant to finalize the treaty, collapsed without agreement on a single article — including the treaty’s objective. Where are we now? The current “Chair’s Text” — the draft agreement guiding negotiations — reflects a deeply divided process. Though it includes measures to improve waste management, on the whole it avoids the most controversial issues: limits on plastic production, regulation of toxic chemicals and how to pay for it all. “There’s a clear majority of countries that have made statements committing to strong measures on chemicals of concern and limiting the production of plastics,” said Sam Winton, a researcher studying the treaty process who is attending the talks. “But there are a small number of countries that consider those topics completely out of the scope of the Treaty.” This resistance comes primarily from oil-producing nations — reportedly led by Saudi Arabia and including Russia and Iran — and plastic-exporting economies that want to focus only on downstream solutions, such as recycling. Meanwhile, ambitious countries — including coalitions led by Rwanda and Mexico — are pushing for upstream controls and legally binding global targets on the use of harmful chemicals and products. Following a July meeting in Nairobi, the Trump administration issued a statement opposing production limits: “We support an agreement that focuses on efforts that will lead to reducing plastic pollution, not on stopping the use of plastics.” What’s at stake? Over 460 million metric tons of plastic are produced annually, of which 20 million end up in the environment. Plastics contaminate virtually every ecosystem on Earth, driving biodiversity and ecosystem loss. Globally, the production, use and waste management of plastics is responsible for 4 percent of total greenhouse gas emissions. But this treaty is about more than environmental protection. It could reshape markets, supply chains and regulations for years to come. For businesses, an agreement would mean: Tighter rules for plastic packaging and product design Restrictions on hazardous chemicals in plastic goods A global push toward reuse, refill and alternative material Increased costs through extended producer responsibility (EPR) laws, such as those in California, Colorado and five other states What will Geneva focus on? The Geneva session will center on four unresolved issues: Scope and ambition Will the treaty cover only waste or the entire plastic life cycle — including how much plastic is made and how? The current draft leans toward a voluntary, national-level approach. Many countries say that’s not good enough, and that a global, enforceable agreement is needed. Plastic production Proposals include setting global targets to reduce the production of primary plastic polymers. Petrochemical-producing nations strongly oppose this, seeing plastics as a growing market for fossil fuels in a world in which demand for energy production will fall in the coming years. Chemicals and products of concern More than 16,000 chemicals are used in plastics, many with unknown health effects. Some countries want to begin phasing out the worst offenders. Others — including industry groups — oppose these moves, citing cost and supply chain complexity. Specific chemicals of concern won’t be decided at these talks, but negotiators could agree to begin to develop a list ahead of future meetings. Finance and implementation Developing countries such as the Philippines, with weak to nonexistent recycling systems, want support to implement the treaty, including technical assistance and a dedicated funding mechanism. Wealthier countries prefer to work through existing platforms such as the Global Environment Facility (GEF). Who pays — and how much — remains unresolved. What are the possible outcomes? There are four broad scenarios for how the Geneva talks could end: Low ambition: A weak treaty focused on voluntary, national-level waste measures. This would be relatively easy to reach but risks being ineffectual. High ambition: A legally binding global treaty covering chemicals, product bans and production limits, along with a roadmap for implementation. This is what many countries want, but it faces stiff opposition in certain quarters. Middle-ground package deal: The most likely scenario: a compromise that trades stronger commitments in one area (such as chemicals) for softer language in another (such as production). Behind-the-scenes negotiations will be key to achieving this. No agreement: If talks fail entirely again, the process could collapse. That could cause some countries to pursue separate high-ambition treaties outside the U.N. Others may fall back on national or regional regulations — creating a patchwork of compliance risks for global businesses. Why this matters The treaty’s outcome will set the direction for plastic regulation, innovation and compliance over the next two decades. A robust agreement would accelerate the shift away from single-use plastics, force businesses to rethink packaging and material choices and create new reporting and transparency requirements across supply chains.Even companies not directly involved in plastic production would face new obligations as part of EPR schemes, product bans or chemical phase-outs. “It is very likely that an ambitious, successful treaty will impact various parts of your operations, probably some parts that you haven’t already thought of,” said Winton. The post As plastics treaty talks enter the final round, here’s what to expect appeared first on Trellis.

CoreTechnologie unveils method for BIM model simplification

The Franco-German software company CoreTechnologie (CT) has introduced a methodology for automating the simplification and conversion of 3D models used in building information modeling (BIM). The latest version of the 3D_Evolution Simplifier tool includes updates aimed at improving efficiency in project development workflows. The software is intended for use by professionals in architecture, construction, mechanical engineering, and plant design. Efficient data reduction for BIM and CAD with the 3D_Evolution Simplifier | Photo Credit: CoreTechnologie GmbH Automated simplification of complex BIM models CAD and IFC models are automatically simplified with the 3D_Evolution Simplifier through significant data reduction using a methodology optimized for BIM models and systems. Easy-to-use simplification and filter functions are executed via scripting in an automated process. The so-called batch manager automatically simplifies large numbers of models and converts them into target formats for established architectural software solutions such as Revit, or into formats like MicroStation IFC, DGN, or DWG. Envelope geometry boosts performance The 3D_Evolution Simplifier enables the smooth conversion of BIM models without losing relevant information or visual quality. File sizes can be reduced by a factor of up to 30 through the generation of envelope geometry. Internal geometry, holes and complex profiles are eliminated, creating envelope geometries while preserving the models outside shape. Also, components not visible from the outside are removed using a special filter function. Performance optimization through instance recognition 3D_Evolution recognizes components that occur multiple times, such as steel beams, doors, windows or screws. These identical geometries are instantiated and then positioned multiple times in the assembly structure. Small parts with very low volume, such as screws, seals or brackets, are identified and automatically removed if needed. This data reduction is especially helpful when passing on data to partners who do not require these details. 3D_Evolution supports both, tessellated geometries for visualizations and exact CAD data for design and planning. All steps can be integrated into existing workflows as automated processes, including customized batch processing of large data volumes. More efficiency for BIM processes 3D_Evolution’s automated model simplification helps streamline handling of large BIM data. It supports faster loading, smoother processing, reduced storage needs, and facilitates internal and external data exchange. For more information, visit coretechnologie.com. The post CoreTechnologie unveils method for BIM model simplification appeared first on Engineering.com.

Georgia launches free rooftop solar and EPA now wants to steal its grant money

Georgia BRIGHT, a statewide initiative to deliver affordable solar, kicked off its “No-Cost Solar Plan” in Atlanta yesterday, giving qualified homeowners a shot at roughly 400 fully prepaid rooftop-solar systems with zero upfront or maintenance costs. However, Georgia Bright’s No-Cost Solar Plan may lose its $156 million in grant money if the EPA steals back the Solar for All program’s entire $7 billion, which funded it. more…

Webinar: Two-stage AC-DC converter for battery charging applications

A virtual prototype of a battery charging design is created with SaberEXP, a piecewise linear circuit simulation tool from Synopsys. Design considerations include charging and discharging profiles, power conversion from grid (AC) to battery (DC), control algorithms are either ASIC based, or software driven. This battery charging design uses a two stage AC-DC converter, comprised of a front-end AC-DC two phase interleaved boost converter delivering constant voltage (600V DC) at the intermediate DC bus. The second stage is a CLLC DC-DC full bridge resonant converter that helps efficient and precise control of power delivered to the battery. The control algorithm is written in C language and tested in the same simulation environment. The outputs of the design can be constant current or constant voltage, ranging from 250V DC to 400V DC and charging current up to 15A. This design uses time-domain simulations conducted under both normal and fault conditions and presents summarized results. Join this webinar at our September Virtual Conference on EV Engineering, presented by Synopsys, to learn how the Saber simulation tool suite offers exceptional flexibility in designing and optimizing both hardware and software, making it a unique platform for improving design quality, reducing design cycle times, and streamlining code debugging. September 18, 2025, 11:45 am EDTRegister now—it’s free! See the complete session list for the Virtual Conference on EV Engineering here. Broadcast live from September 15 to 18, 2025, the conference content will encompass the entire EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

Tesla Cybertruck leftovers are the main course at the Supercharger Diner

Tesla Cybertruck panels that are leftover from manufacturing became the main course at the Supercharger Diner, contributing to the futuristic restaurant’s unique exterior design. The Supercharger Diner was an idea of Tesla CEO Elon Musk’s in 2018, and in July 2025, it officially opened for business, serving a variety of interesting dishes in a futuristic setting that pays homage to the 1950s restaurant experience. The design of the Diner is what truly sets it apart: it is reminiscent of the stainless exterior that Tesla used for the Cybertruck. It turns out that’s exactly what it is. Credit: Tesla Tesla Chief Designer Franz von Holzhausen revealed in an interview with Tesla Owners Club Austria that the company used recycled panels from Cybertruck manufacturing as siding on the epic diner. Here’s what he said: Tesla Diner was inspired by the Jetson‘s and was built with steel from @cybertruck production pic.twitter.com/3t4038RY4H — Tesla Club Austria (@TeslaClubAT) August 4, 2025 Tesla sourced its stainless steel for the exoskeleton of the Cybertruck from Steel Dynamics Inc. and its plant in Sinton, Texas. The company confirmed this through various outlets, including exhibit descriptions at the Petersen Automotive Museum. The steel is refined through a third party before it is used. Credit: Cybertruck Owners Club It also uses the same steel for SpaceX Starship. It’s pretty interesting that Tesla chose to use the stainless steel for the exterior of the diner in Los Angeles, but it also makes sense considering how durable it has proven to be. The post Tesla Cybertruck leftovers are the main course at the Supercharger Diner appeared first on TESLARATI.

Tesla ‘activist shareholders’ sue company and Elon Musk for Robotaxi rollout

Tesla’s “activist shareholders” seem to be one of the biggest threats to the company and its CEO, Elon Musk, who has spoken extensively about them in recent times. They’re up to their latest bit of work against the company, suing both Tesla and Musk, accusing them of securities fraud by alleging they concealed “significant risk” over the Robotaxi launch in Austin, Texas. On Monday night, a group of shareholders sued Tesla and Musk in a proposed class action lawsuit in Texas federal court. They claim Tesla misled investors about the safety of the vehicles used in the Robotaxi rollout in Austin, which started on June 22. The suit indicates that videos show the vehicles “speeding, exhibiting sudden braking, driving over a curb, entering the wrong lane, and dropping passengers off in the middle of multilane roads.” Reuters first reported on the lawsuit. The plaintiffs are seeking damages for shareholders between April 19, 2023, and June 22, 2025. Tesla’s Robotaxi platform has been operating for less than two months, and the company has already expanded its geofence in Austin twice. Tesla Austin Robotaxi geofence sizes (in square miles): Initial: 6/22 – ~20 square miles First Expansion: 7/14 – ~42 square miles Second Expansion: 8/3 – ~80 square miles pic.twitter.com/IwnvSJseE4 — TESLARATI (@Teslarati) August 3, 2025 In the roughly six weeks that Robotaxi has been operational, Tesla has only had one incident reported to the Austin Government, and it was a “Safety Concern” in June 2025. Since July 2023, which is when autonomous vehicle operation began in Austin, 130 incidents have been reported. AV Ride, Cruise, Waymo, and Zoox also operate in Austin. Waymo has the most incidents with 73. Its first was in June 2024 when a unit blocked traffic. Activist Shareholders Musk has warned that activist shareholders are potentially dangerous to both Tesla and his position as CEO. He recently spoke about them during the Q2 Earnings Call regarding his stake in the company: “That is a major concern for me, as I’ve mentioned in the past. I hope that is addressed at the upcoming shareholders meeting. But, yeah, it is a big deal. I want to find that I’ve got so little control that I can easily be ousted by activist shareholders after having built this army of humanoid robots. I think my control over Tesla, Inc. should be enough to ensure that it goes in a good direction, but not so much control that I can’t be thrown out if I go crazy.” Tesla’s Board yesterday made an attempt to help secure Musk’s stake by offering him a massive 96 million share pay package of restricted stock. It will only help his stake in the company bump up slightly to 14.6 percent from 12.9 percent. The post Tesla ‘activist shareholders’ sue company and Elon Musk for Robotaxi rollout appeared first on TESLARATI.