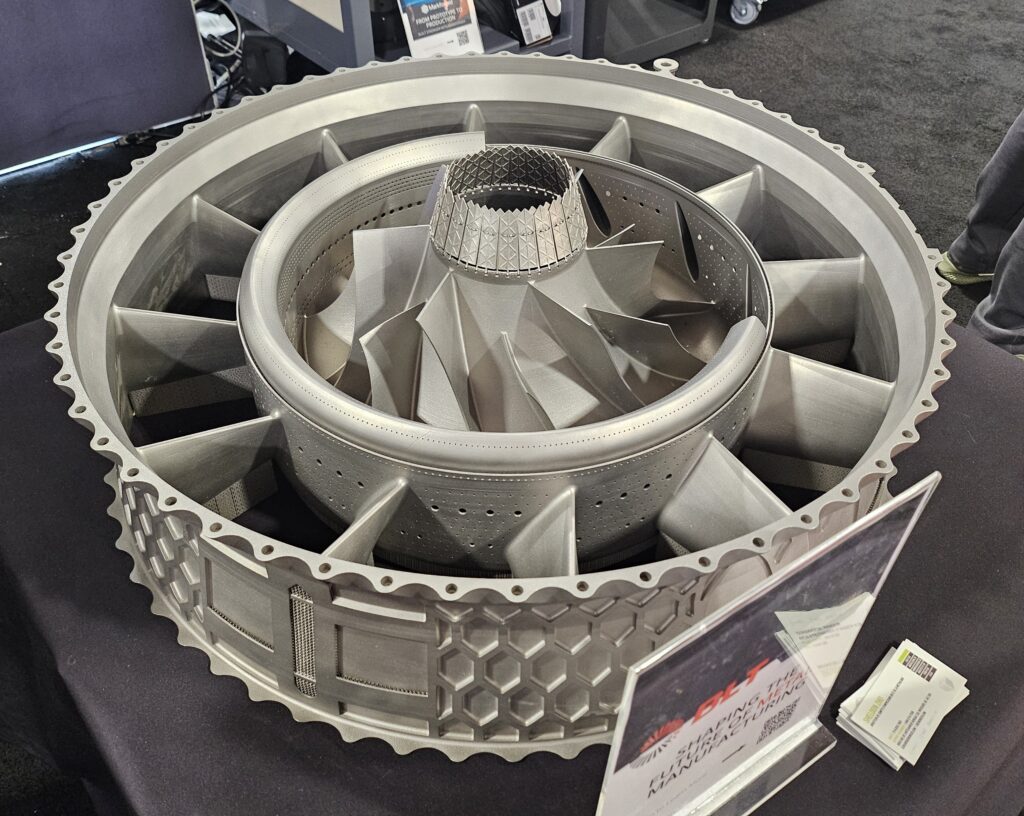

Metal additive manufacturing on the show floor at CMTS. (IMAGE: Author)

Let me start by apologizing for the interjection in the headline.

I feel very fortunate to live in Canada and, honestly, I cringe at many of the stereotypical markers of our national identity. Nevertheless, I’m admittedly guilty of this particular Canadianism on a regular basis. But more than that, I chose this (undeniably pedestrian) headline because it captures a sentiment I came across repeatedly while walking the floor at this year’s Canadian Manufacturing Technology Show (CMTS).

Show floor safari

At a glance, one manufacturing trade show looks very much like another. Whether it’s the International Manufacturing Technology Show in Chicago, FABTECH in Las Vegas, or EMO in Hannover/Milan (depending on the year), you’ll probably see more-or-less the same sights:

- Rows of exhibition booths featuring various components and the industrial equipment that makes them

- Attendees wandering up and down the aisles, admiring said components and equipment

- Sales people eagerly trying to engage said attendees however they can, with tables of swag laid out like all-you-can-eat buffets

- Packs of students dashing from one booth to the next, grabbing said swag and stuffing it into their tote bags (also swag)

- Trade journalists trying to grab comments and interviews from all of the above, competing for attention while neither selling nor buying (nor giving away) anything ourselves

Really, aside from the first two points, what I described probably characterizes 99% of trade shows in any sector, not just manufacturing. Yet despite these superficial similarities, there are significant differences between trade shows, even just within manufacturing.

What sets CMTS apart, ironically, is its lack of differentiation.

Printing inside the box

“I’ve been to different booths [on one side of the hall] and seen a lot of automation,” says Rishabh Sharma, applications specialist at GoEngineer, which had its booth roughly in the middle of the exhibition hall. “Then I went to the other side this morning and saw a lot of really cool innovations with 3D printing. I’ve noticed a lot of people are attracted towards the printers.”

Sharma isn’t unique in that impression.

Mark Pimentel, senior CAM application specialist at Hawk Ridge Systems, tells me, “I’ve been in the business long enough that I’ve seen interest in certain things grow. For some reason, at this show I’m getting a lot of questions about 3D printing, and there’s a good representation of 3D printing here.”

Unlike its larger American and European counterparts, CMTS brings a multitude of different manufacturing technologies into a single hall. As a result, a short walk can see you passing booths for software, additive manufacturing (AM), waterjet cutting, CNC machining, contract manufacturers, and universities in the span of just a few minutes. It may not be the biggest or most specialized trade show, but its relatively small size and that lack of specialization make some technologies – such as 3D printing – really stand out.

“Compared to four years ago, the show feels tighter,” observes Terral Childs, mechatronics engineer laboratory manager for the engineered solutions group at Mitsubishi Electric. “Right now we’re a bit compact, which is a good thing: the close proximity actually allows more people to see everyone at the show no matter where you’re located.”

Yama Fedai, key account manager and industry manager for automotive at TRUMPF, emphasizes the variety of people with vested interests in manufacturing attending the show. “It’s more diverse than other industry trade shows,” he says. “We ran into folks from University of Waterloo, we saw automotive and aerospace folks. In many ways – including AM – what surprised me is the diversity of folks that are here.”

CAN AM

With so much buzz around additive, one might be forgiven for thinking that there’s some cutting-edge Canadian 3D printing going on. But, for the most part, the people actually in the AM industry at the show noted a lag in the adoption curve above the 49th parallel – a common complaint in the Canadian tech industry more broadly.

“In general, Canada is typically slower to adopt international technology,” says Chris Niedojadlo, director of sales and marketing at 3D Printing Canada. “Trends in Europe and the US today might be six to twelve months ahead of what Canada’s adopting.”

David Nolan, founder of Sixpenny Additive, sees an even wider margin: “What I’ve learned is that the States is five years ahead and Europe is like ten years ahead of where we are. Both of those adoption curves are essentially exponential, and we’re still on the flat part of the slope. I think that hesitancy has largely been a result of people not understanding what’s available and not having access to the machinery.”

Nolan is aiming to change that with his company, which premiered at CMTS, and aims to act as both a service provider and reseller of metal AM technology. It’s a business model that seems to have become more popular in the AM industry in recent years so, in that sense, Canada lagging behind Europe and the United States could actually be to the advantage of Canadian AM: learning the hard-won lessons of what it takes to drive adoption without the growing pains.

Perhaps the most striking suggestion that the Canadian AM industry is growing came from Karim Jassir, content marketing strategist for Renishaw Canada. After telling me that this was the company’s first time back at CMTS in eight years, he mentioned that, “There was an intention from SME to have a separate building focused on just additive manufacturing but, sadly, that had to be reduced because of everything that’s been happening.”

Even so, Jassir emphasized that this was the right time for Renishaw to return to CMTS: “There’s a lot of people coming to the show and, so far, we’ve had really good feedback.”

The post Additive manufacturing, eh? appeared first on Engineering.com.